menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

Magnetic grid

Magnetic grid

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

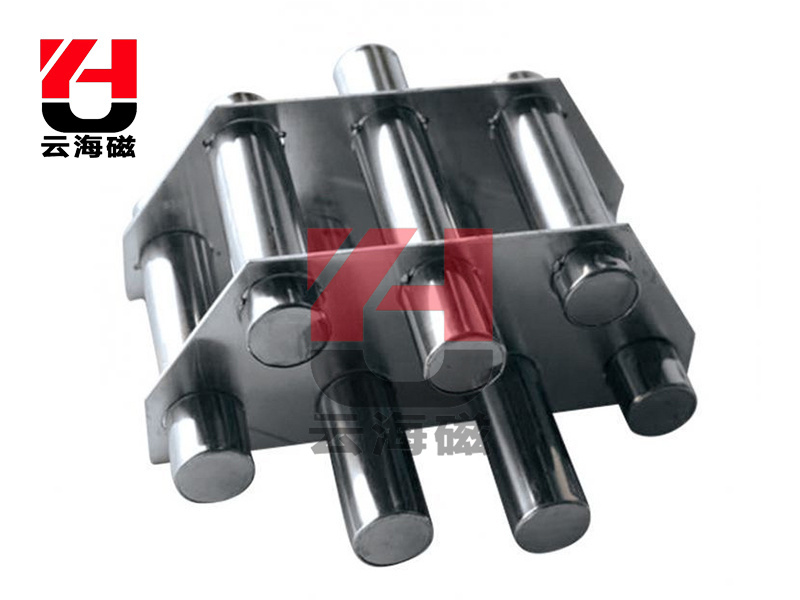

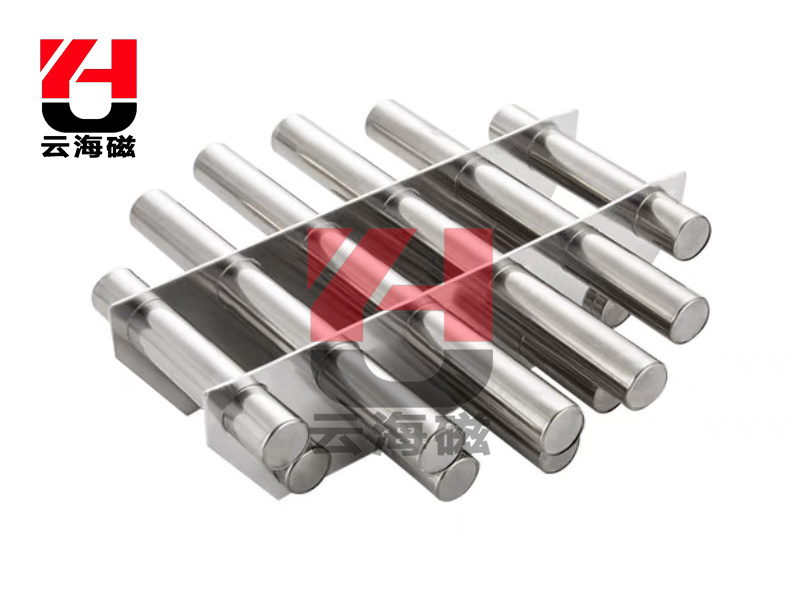

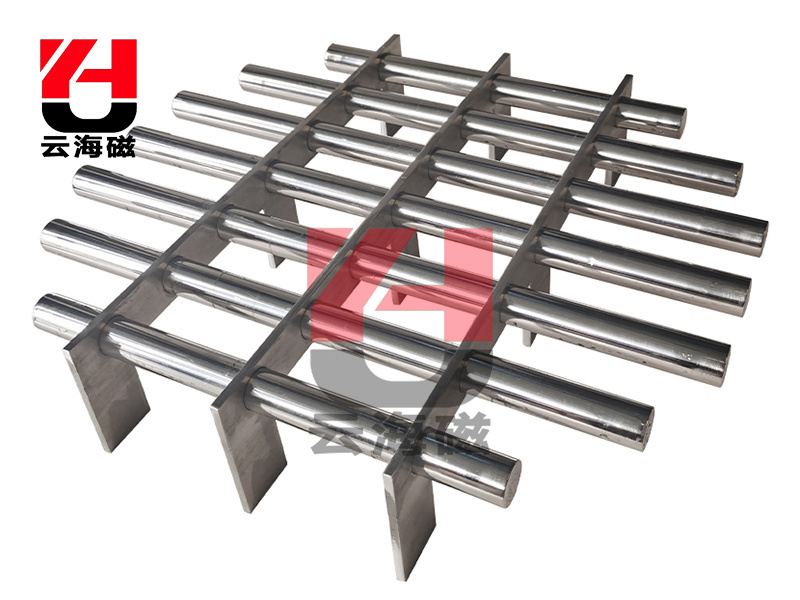

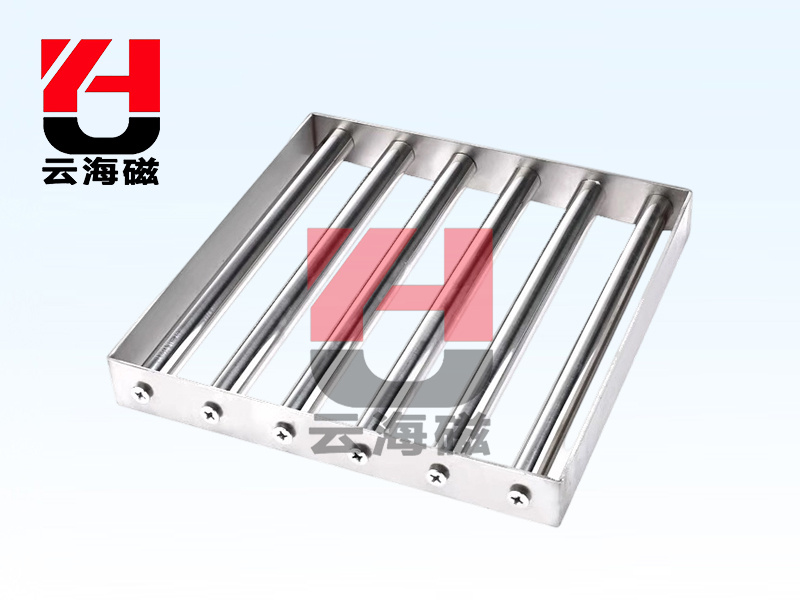

Magnetic grid

Product Introduction

Magnetic grid, also known as magnetic frame, is formed by fixing magnetic rods with stainless steel plates in different shapes and sizes according to different usage requirements. Magnetic grids can be installed in feeding hoppers, discharge ports, conveying pipelines, etc. When materials flow through the magnetic grid, iron impurities will be firmly adsorbed on the magnetic rod, thereby achieving the effect of purifying materials and protecting the safe operation of downstream equipment. Magnetic grid can be used to filter small iron impurities carried in powders, particles, liquids, and gases

Product selectivity

1. Surface treatment: mirror polishing, wire drawing polishing;

2. Surface material: SS304, SS316;

3. Magnetic strength grade of magnetic rod: 3000Gs, 10000Gs, 12000GS;

4. Working temperature<: 80 ℃, 100 ℃, 120 ℃, 150 ℃, 180 ℃, 200 ℃, 250 ℃, 300 ℃;

5. Size and shape: The size and shape can be made into multi-layer, circular, irregular polygon, semi-circular, etc. according to requirements;

6. Cleaning methods: conventional type, easy to clean casing type;

7. Accessories can be selected: handle, guide rod, and guide plate.

Scope of Application

Magnetic grilles are mainly used in industries such as food, fine chemicals, and injection molding. Generally, ferrite permanent magnet materials are commonly used in the injection molding industry, with a surface magnetic field strength of around 2000 Gauss; The food and fine chemical industries use magnetic grids, which are mostly made of rare earth neodymium iron boron magnets. The surface magnetic field strength is between 6000 and 12000 Gauss, which is much stronger than the magnetic force of ferrite magnetic grids. During use, the particle size of adsorbed iron impurities will be finer, and the adhesion force will be stronger.

product image

location:

location: