menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

CXJ dry powder magnetic separator

CXJ dry powder magnetic separator

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

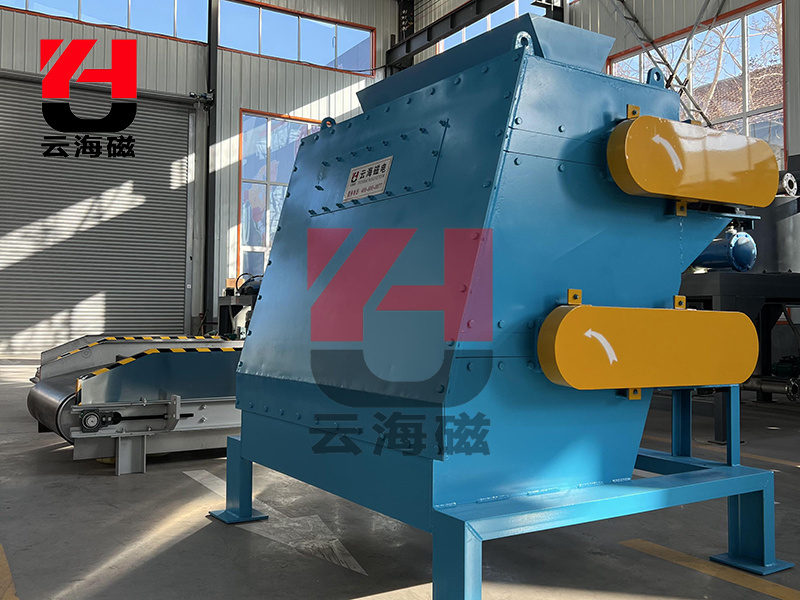

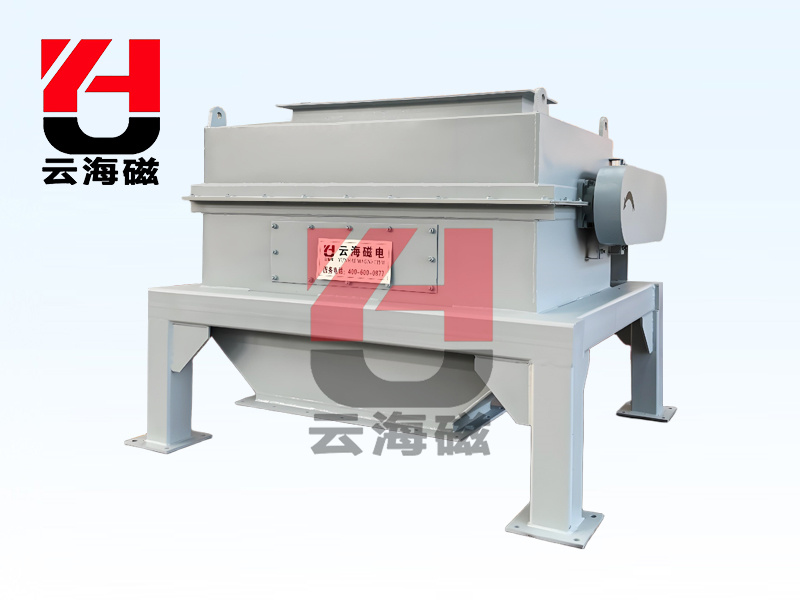

CXJ dry powder magnetic separator

Product Introduction

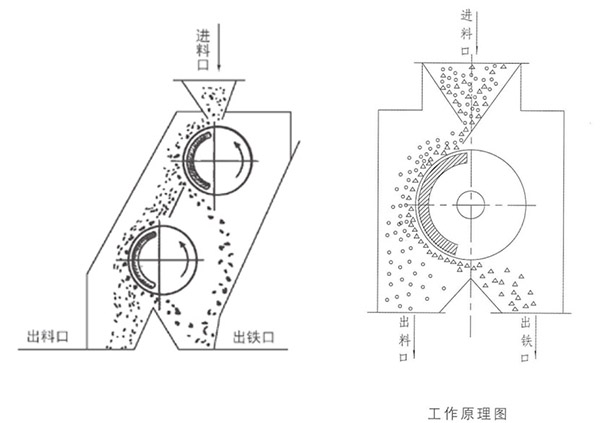

This equipment is a magnetic separation device that continuously and automatically removes iron from dry powder materials. It adopts a unique magnetic circuit design inside, divided into single cylinder to four cylinder designs, and uses high-performance permanent magnet neodymium iron boron material as the magnetic source. The magnetic field is strong, the suction force is large, and the iron removal rate is high. It has the characteristics of maintenance free, energy-saving, safe and reliable use, and can adjust and control the feeding amount, suitable for the requirements of different particles. The product is widely used in industries such as abrasives, refractory materials, non-metallic mineral processing, carbon black, grain, feed, chemical raw materials, etc.

Technical Features

1. A permanent magnet drum designed with the latest rare earth permanent magnet material neodymium iron boron is used to increase the magnetic field strength and ensure that the demagnetization rate does not exceed 8% within eight years.

2. Concentrate the magnetic field lines on the outside of the magnetic drum through which the material passes, forming a working area with high surface magnetic field and high magnetic field gradient, which has strong adsorption force on magnetic materials and is suitable for use in various harsh environments except for high temperature.

3. The magnetic system design adopts a multi pole structure, increasing the number of magnetic flips, reducing the magnetic flip width, and increasing the magnetic flip frequency, which is conducive to the discharge of iron impurities in the material and improves the grade of the sorted material.

4. Easy to operate, the sealed design of the magnetic system will prolong the working life.

5. The equipment can be connected to the production line for continuous operation.

6. The surface of the drum is protected by wear-resistant materials, and the overall design is made of 304 stainless steel and carbon steel.

7. There are various magnetic fields to choose from based on the particle size, shape, and iron content of the customer's materials.

Technical Specifications

| Parameters/Project/Model | Dimensions mm | Roller length mm | Drum diameter rmm | Magnetic induction intensity Gs | Number of drums | Drum speed r/min | Productivity T/h | Material particle size mm | Motor power kw |

| CXJ-40-Ⅰ | 550×460×660 | 400 | 300 | 1000-10000 | 1 | 17-82 | ≤0.6 | ≤5 | 0.55 |

| CXJ-60-Ⅰ | 830×710×930 | 600 | 400 | 1 | ≤1.5 | ≤5 | 0.75 | ||

| CXJ-60-Ⅱ | 1070×925×1240 | 600 | 320 | 2 | ≤2 | ≤5 | 1.5 | ||

| CXJ-60-Ⅲ | 1150×1070×1700 | 600 | 406 | 3 | ≤2.5 | ≤6 | 1.5 | ||

| CXJ-80-Ⅰ | 1180×820×1040 | 800 | 406 | 1 | ≤2 | ≤8 | 0.75 | ||

| CXJ-80-Ⅱ | 1420×1220×1570 | 800 | 406 | 2 | ≤2.5 | ≤8 | 1.5 | ||

| CXJ-80-Ⅲ | 1770×1260×1570 | 800 | 406 | 3 | ≤3 | ≤8 | 2.2 | ||

| CXJ-100-Ⅰ | 1300×1020×1240 | 1000 | 508 | 1 | ≤2.5 | ≤10 | 3 | ||

| CXJ-100-Ⅱ | 1620×1420×1770 | 1000 | 508 | 2 | ≤4 | ≤10 | 4 | ||

| CXJ-100-Ⅲ | 1970×1460×2309 | 1000 | 508 | 3 | ≤5.5 | ≤10 | 5.5 |

product image

on-site installation

location:

location: