CBK type rotating magnetic rod iron remover

Product Introduction

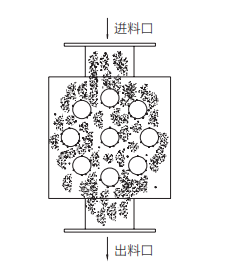

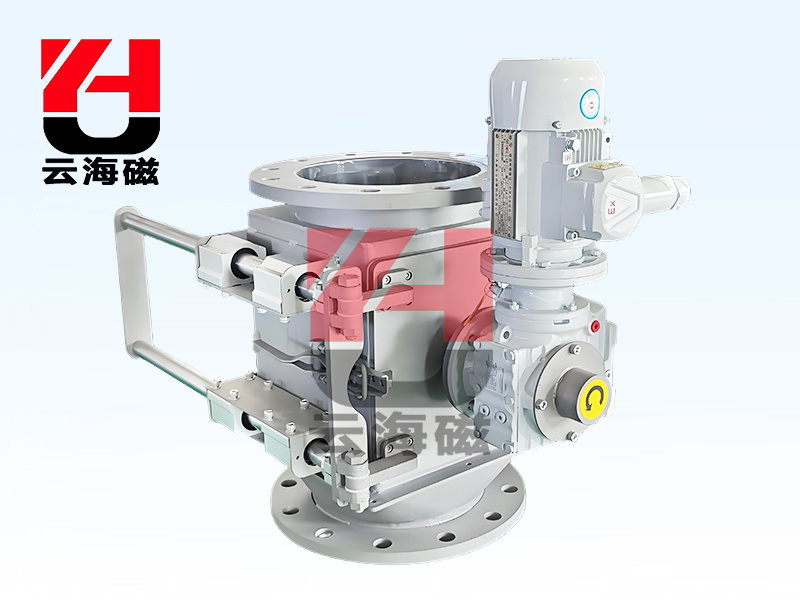

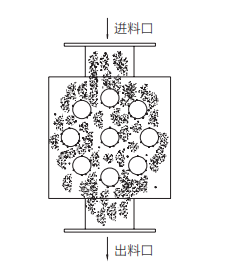

The rotary iron remover consists of three parts: a circular magnetic grid, a stainless steel box, and a reduction motor. The rotary iron remover is driven by a reduction motor to rotate the circular magnetic grid, effectively avoiding situations such as bridging and blocking when the material flows through the iron remover, and effectively removing iron impurities from loose and agglomerated materials. The rotary iron remover is mainly used to sort small iron impurities in powder materials with relatively poor fluidity and easy accumulation. These materials are prone to blockage or accumulation when using traditional magnetic racks or drawer type iron removers. Widely used in production lines of industries such as food, food additives, pharmaceuticals, fine chemicals, lithium battery positive and negative electrode materials, pigments, carbon black, flame retardants, etc.

Application field

The industries of iron removal for all 10-500 mesh fine powder materials, including corn starch, cocoa powder, fructose, jam, gypsum powder, barium carbonate, sawdust, dehydrated vegetables, Chinese herbal medicine, glass fiber, quartz sand, potassium feldspar, mica, micro powder, fly ash, etc.

Installation location

1. Inlet (outlet), the front or end of the production line

2. Free scattering, series connection with the pipeline for conveying materials, and standalone use of bulk materials.

Product Features

1. Rotating structure allows for smooth circulation of ultrafine powder materials, preventing material clumping and blockage.

2. The magnetic field exceeds 12000 Gauss and the temperature resistance can reach 300 ℃.

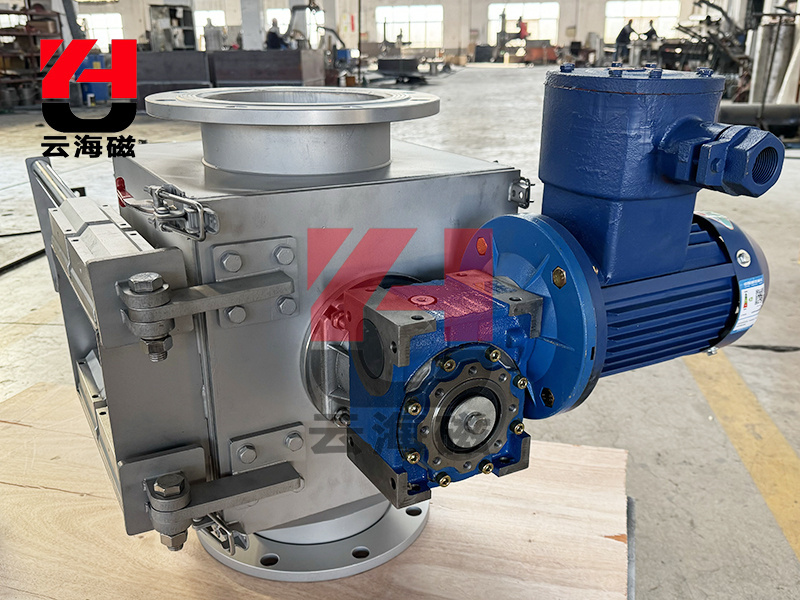

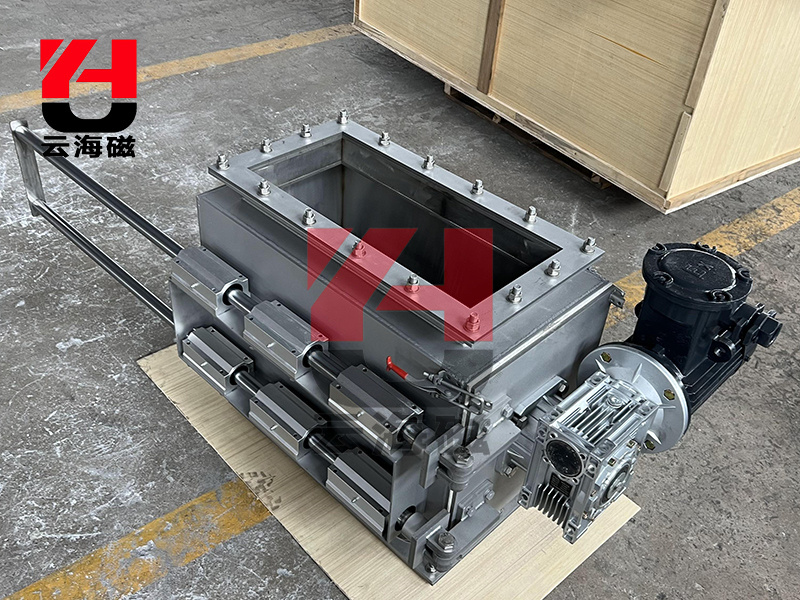

3. Various connection methods, such as clamps, flexible connections, flanges, or optional circular or rectangular pipes, as well as joint sleeves

4. We offer various types and sizes of products, and can customize designs according to customer requirements.

5. The unloading method is manual unloading.

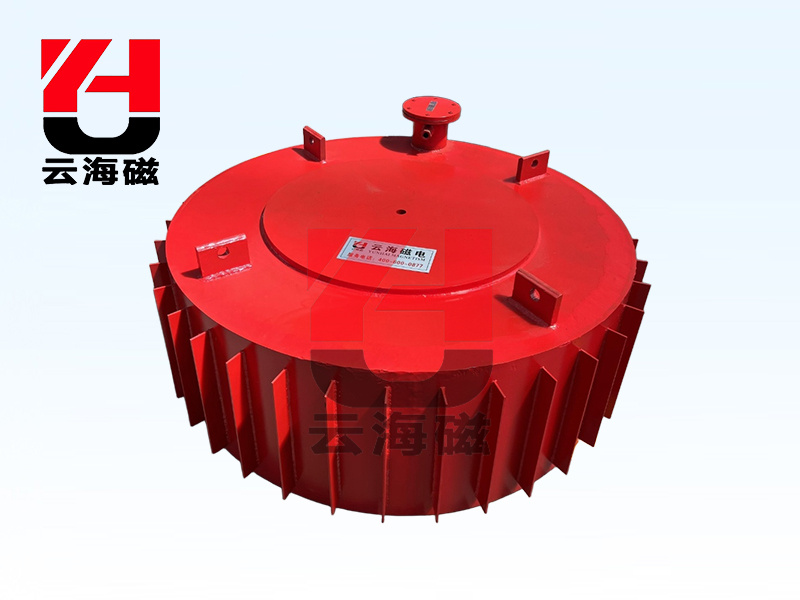

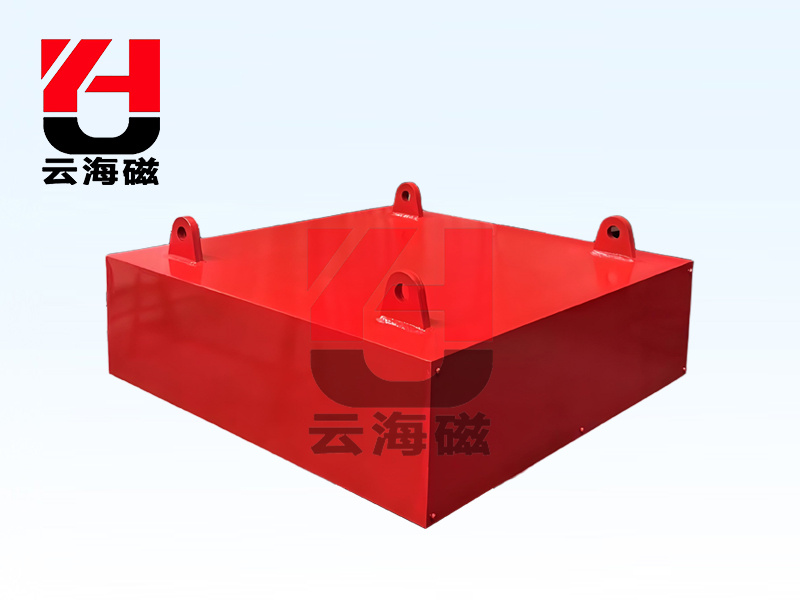

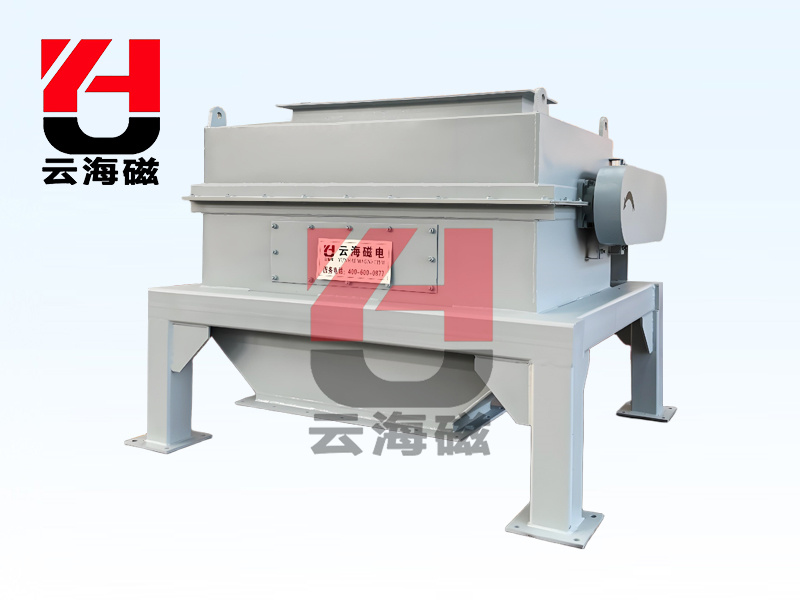

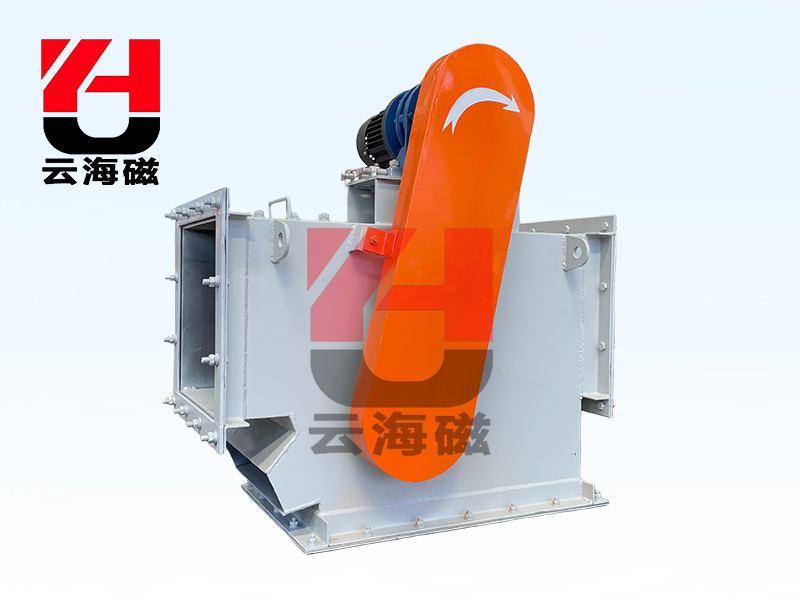

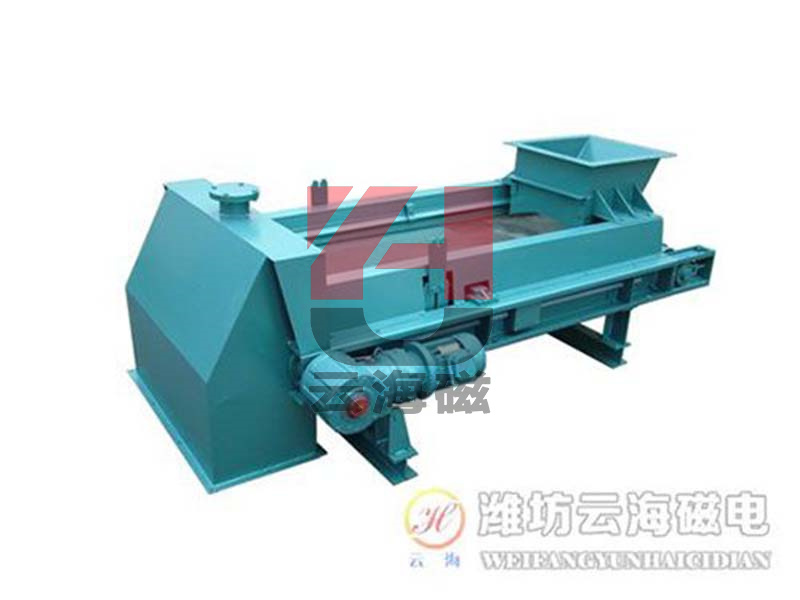

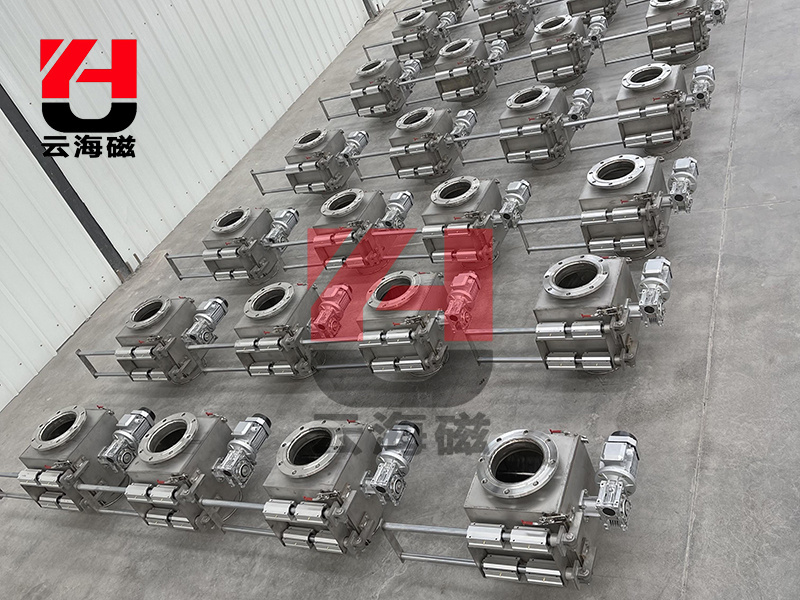

product image

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE