RCYA permanent magnet pipeline iron remover

Product Introduction

The RCYA series pipeline permanent magnet iron remover produced by our company is a new generation of pipeline permanent magnet iron remover developed and designed by ourselves, which combines the advantages of similar equipment at home and abroad. This series of products is used in conjunction with conveyor belts, vibration conveyors, chutes and other conveying equipment, and can remove 0.1-50KG of ferromagnetic substances mixed in bulk materials. It plays a reliable protective role for various types of crushing equipment such as crushers and grinders, and is also used to improve the taste and purification of raw materials, as well as to recover ferromagnetic substances from materials.

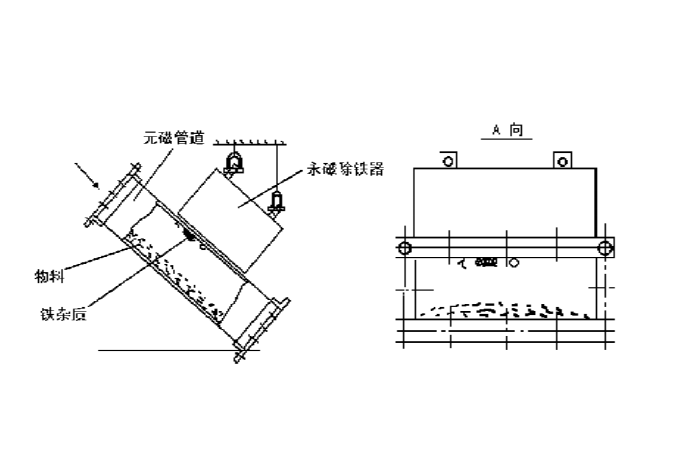

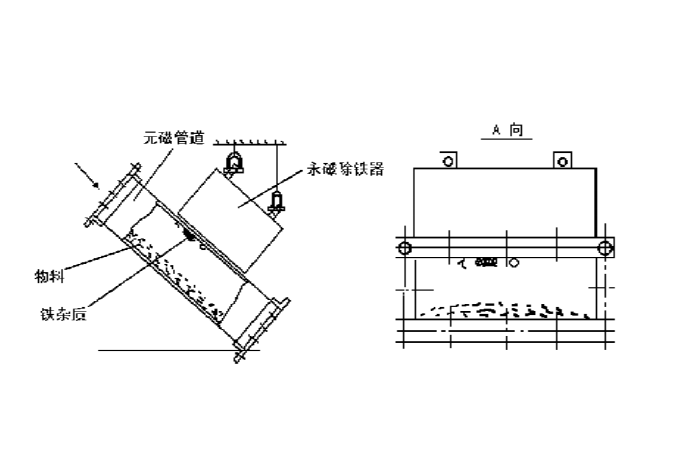

Working principle and installation diagram

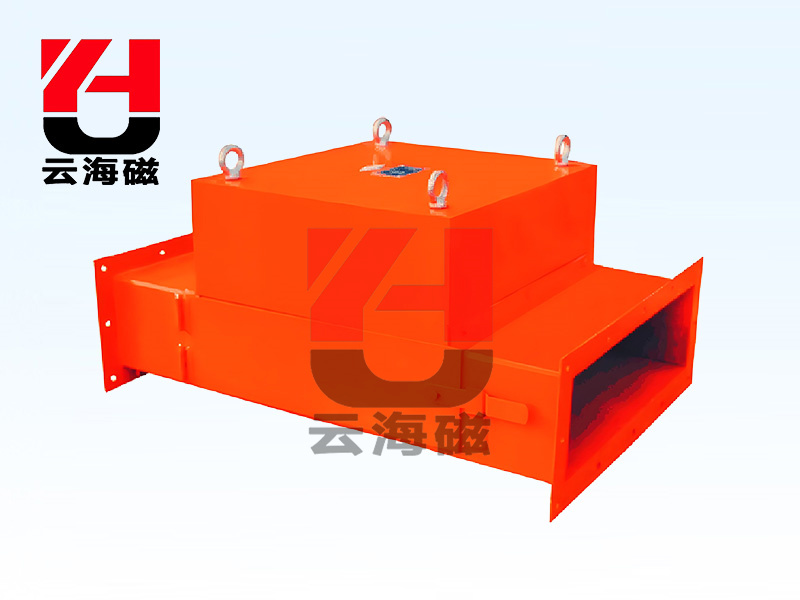

The RCYA series pipeline permanent magnet iron remover includes two parts: non-magnetic pipeline and permanent magnet, dedicated to removing iron from non-magnetic materials in closed pipelines. The interior of the permanent magnet iron remover is composed of a composite magnetic system made of high-performance hard magnetic materials. It has small size, strong magnetic force, light weight, clean iron removal, and is convenient. Features such as no energy consumption and long service life. Suitable for situations where there is no conveyor belt and only a discharge chute can be provided. When the bulk material passes through the pipeline type permanent magnet iron remover, the iron impurities are adsorbed by the high field strength permanent magnet. When removing the iron impurities, open the pipeline dedicated door to remove the impurities. Mainly used for removing debris in the discharge pipelines of industries such as cement, chemical, plastic, refractory materials, and building materials.

Equipment installation and maintenance

1. During installation, the equipment must have sufficient installation and be bolted to the flange of the material pipeline

2. When installing the equipment, first make a bracket based on the external dimensions and suspension dimensions of the iron remover, then install the iron remover above the belt and firmly fix it on the bracket. The angle between the steel wire ropes of the two lifting rings should not exceed 90 degrees

3. After the iron remover is put into operation, the ferromagnetic substances adsorbed on the iron remover should be cleaned regularly according to the time. If not cleaned in time, material blockage may occur. When cleaning, the observation port on the pipeline should be cleaned

4. If encountering metal substances that cannot be adsorbed by the iron remover, users can install our company's metal detector to detect harmful metals.

5. Do not bring iron tools near the iron remover during operation, and do not remove iron blocks from the iron remover by hand to avoid personal accidents.

Technical Specifications

| Parameters/Project/Model | Adapt to yield≤ T/h | Pipeline external dimensions mm | Dimensions of permanent magnets mm | External dimensions of flange interface mm | Adapt to the angle between the slope and the ground | weight kg | Material adaptation |

| RCYA1-15 | 15 | 800×450×140 | 500×300×200 | 510×200 | 40°-50° | 210 | Small chunks of material |

| RCYA1-30 | 30 | 900×550×170 | 600×400×240 | 610×230 | 260 |

| RCYA1-50 | 50 | 1000×650×190 | 700×500×240 | 750×290 | 420 |

| RCYA1-80 | 80 | 1100×750×200 | 800×600×260 | 850×300 | 825 |

| RCYA1-100 | 100 | 1200×850×220 | 1000×700×300 | 950×320 | 1050 |

| RCYA1-150 | 120 | 1300×1000×240 | 1150×650×320 | 1100×340 | 1280 |

| RCYA1-200 | 200 | 1400×1200×280 | 1350×800×340 | 1300×380 | 1650 |

| RCYA1-300 | 300 | 1600×1400×310 | 1550×1200×380 | 1540×450 | 2400 |

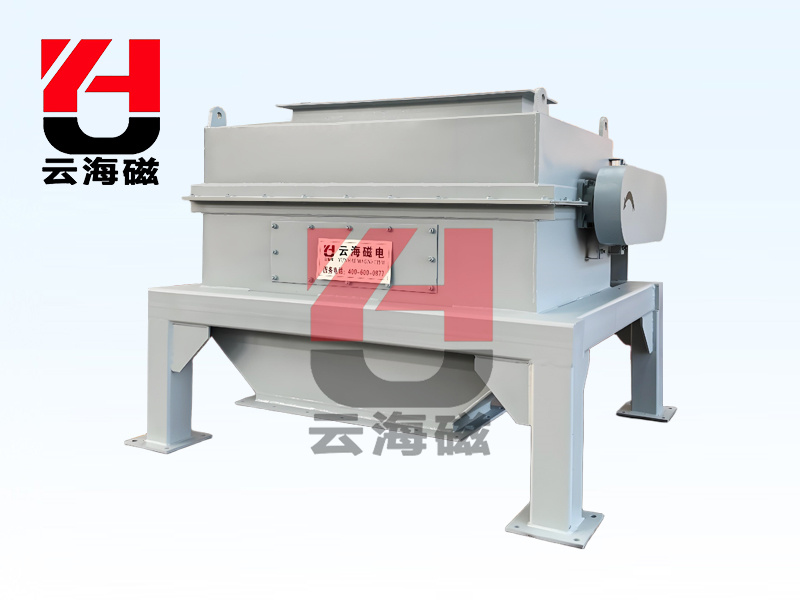

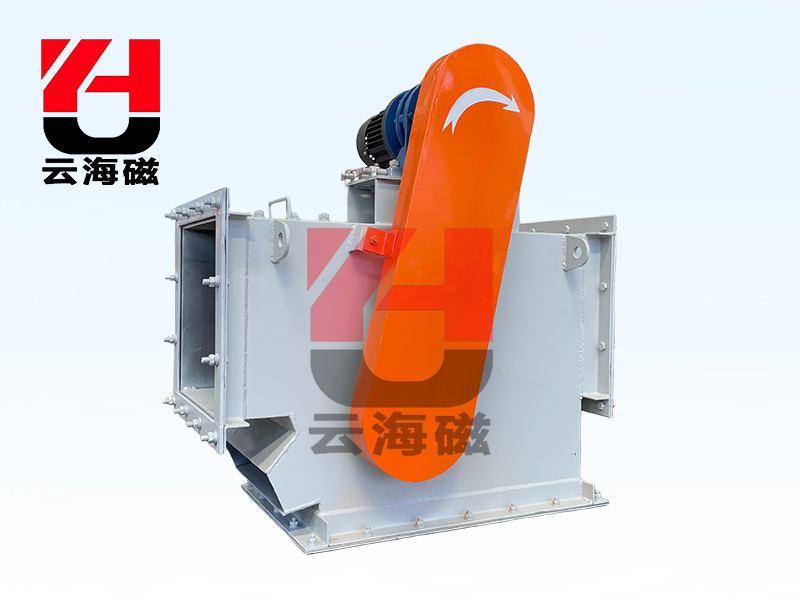

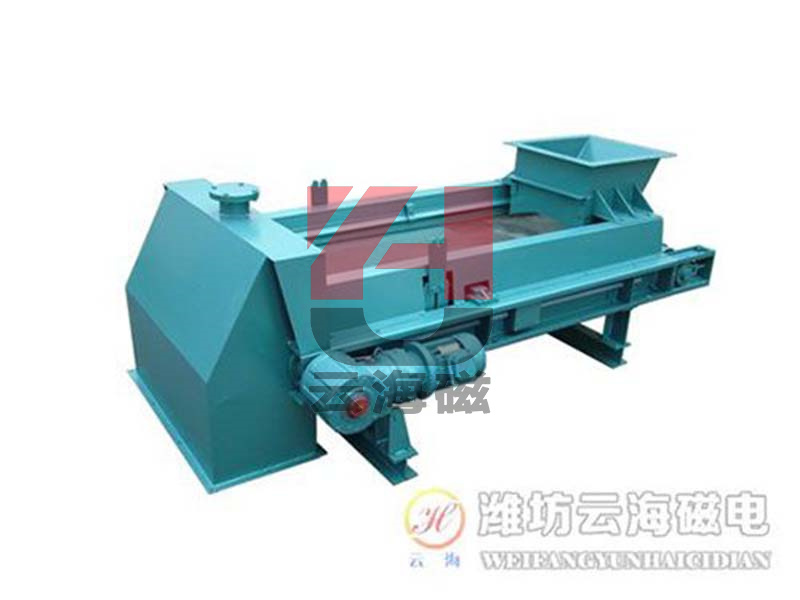

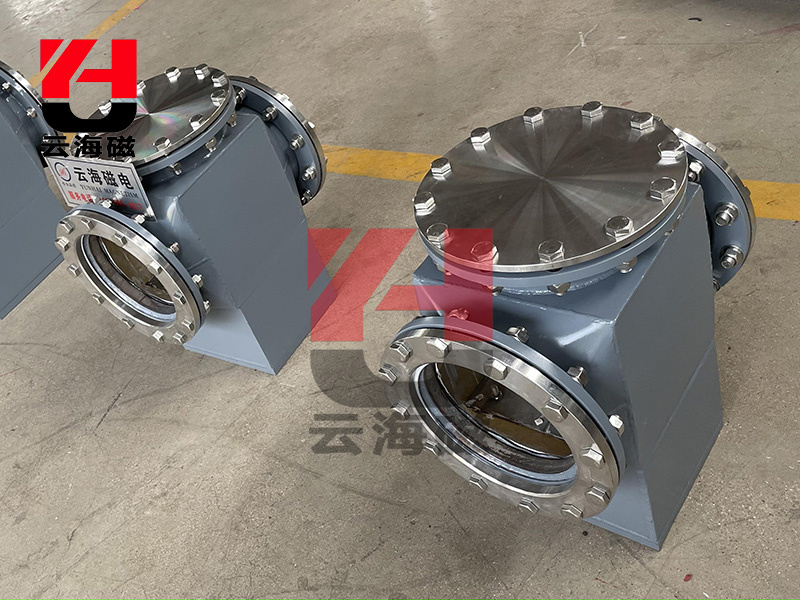

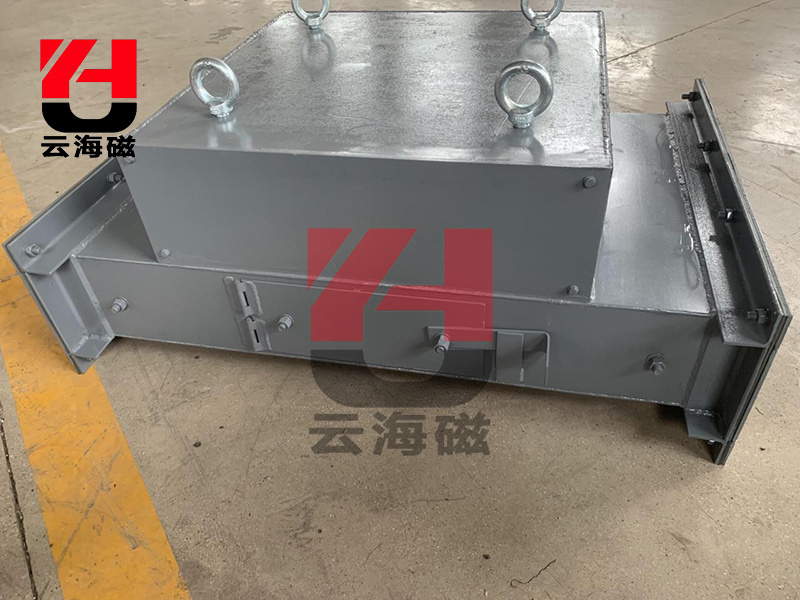

product image

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE