RCGZ pipeline self dumping iron remover

Product Introduction

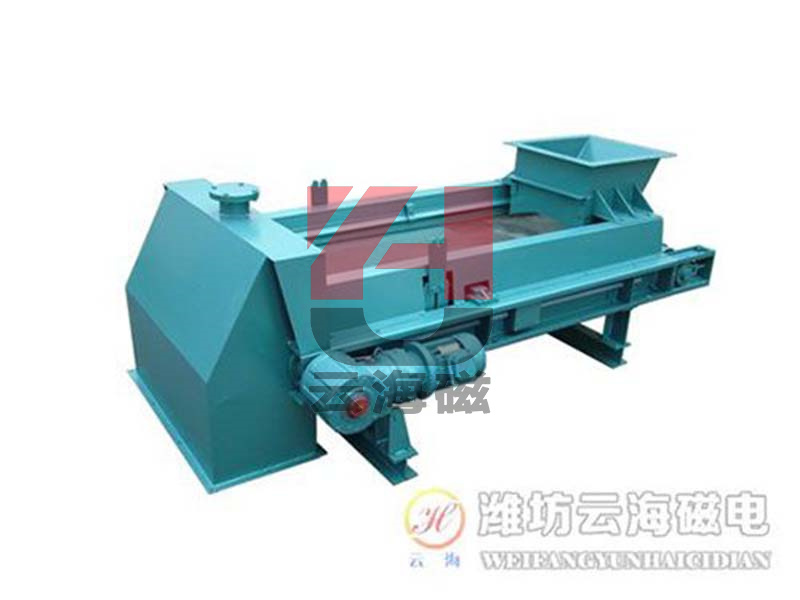

The RCGZ series pipeline type permanent magnet automatic iron remover consists of three main parts: the pipeline body, the driving device, and the magnet running device. The driving device is installed on the pipeline wall and drives the magnet running device in the magnetic separation chamber inside the pipeline through a sprocket and chain. The permanent magnet discharges the mixed ferromagnetic substances in the pipeline material through the iron outlet. This equipment is mainly used in the cement industry to remove iron from the coarse powder after powder selection by the powder selection machine and the fine powder before entering the grinding after clinker pre crushing, in order to prevent iron particles from accumulating in the grinding machine and improve the production efficiency of the grinding machine. The iron removal before the cement filling process can automatically clean and discharge the iron impurities mixed in the cement, ensuring stable production operation.

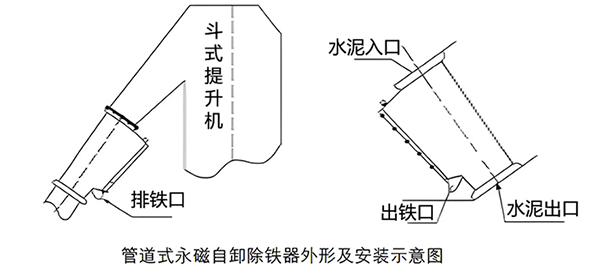

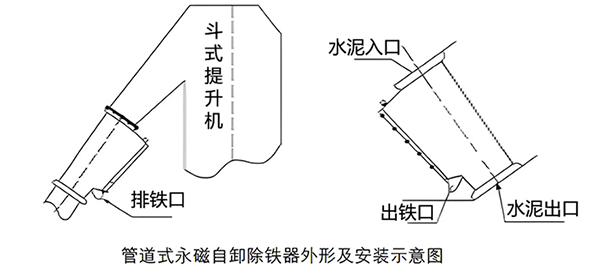

Working principle and installation diagram

The RCGZ pipeline self dumping iron remover is connected in series with a material conveying pipeline with an inclination angle of 45 ° to 75 °. When the material flows through the iron remover, the ferromagnetic substance in it is adsorbed onto the stainless steel wall of the pipeline iron remover and gradually slides towards the iron outlet direction with the movement of the permanent magnet, achieving separation from the material. At the tapping hole, as the permanent magnet moves away in the direction of cyclic motion, the ferromagnetic material loses its magnetic attraction and is discharged from the tapping hole under the action of gravity, achieving automatic iron removal of the material.

Technical Features

This equipment uses neodymium iron boron with high remanence as the magnetic source, which has high iron removal efficiency and long service life.

⑵ The power source adopts a low-power cycloidal pinwheel reduction motor, and the transmission adopts a precision roller sprocket, which has the advantages of small size, light weight, reliable and stable operation, and few faults. It is easy for users to use and easy to maintain.

The structure design of this equipment is reasonable, compact, easy to install, and can be used by connecting it in series with the material conveying pipeline.

The iron removal process is continuous and automatic, and no supervision is required after the equipment is started.

Suitable for enclosed material conveying systems, with no dust escaping during operation and no environmental pollution.

Technical Specifications

| Project/Parameters/Model |

Adapt to yield T/h |

Pipeline external dimensions mm | Flange interface size mm | Adapt to slope | working method | Adapt to granularity mm |

Motor power Kw |

weight kg |

| RCGZ-3 | 100 | 1450×350×350 | 450×450 |

|

| ≤25 | 0.55 | 350 |

| RCGZ-4 | 150 | 1450×450×350 | 560×460 |

|

| 0.55 | 550 |

| RCGZ-5 | 200 | 1450×500×500 | 600×600 | 55° | Continuous automatic | 0.55 | 780 |

| RCGZ-6 | 400 | 1600×800×500 | 900×600 | ~ |

| 0.75 | 1100 |

| RCGZ-7 | 600 | 1600×900×500 | 1000×600 | 66° |

| 1.5 | 1800 |

| RCGZ-8 | 800 | 1800×1000×600 | 1100×700 |

|

| 1.5 | 2300 |

| RCGZ-10 | 1000 | 1800×1200×650 | 1300×750 |

|

| 2.2 | 2800 |

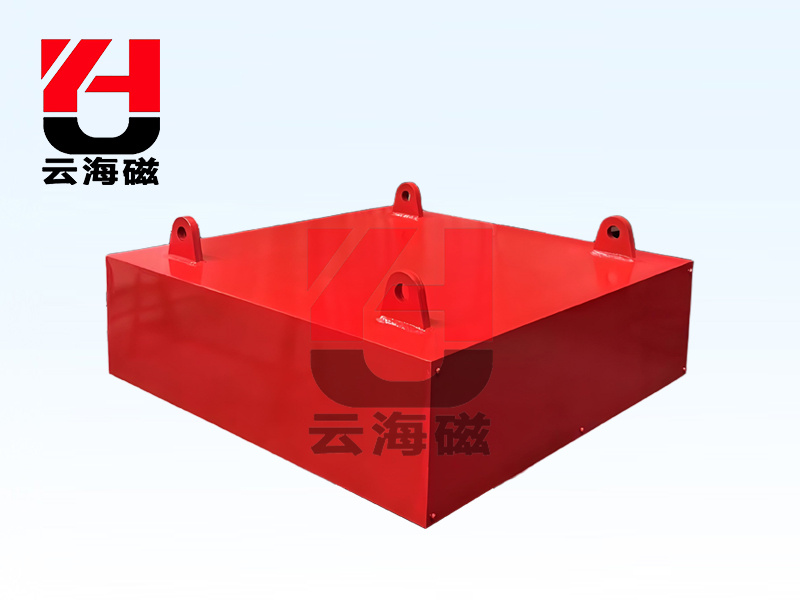

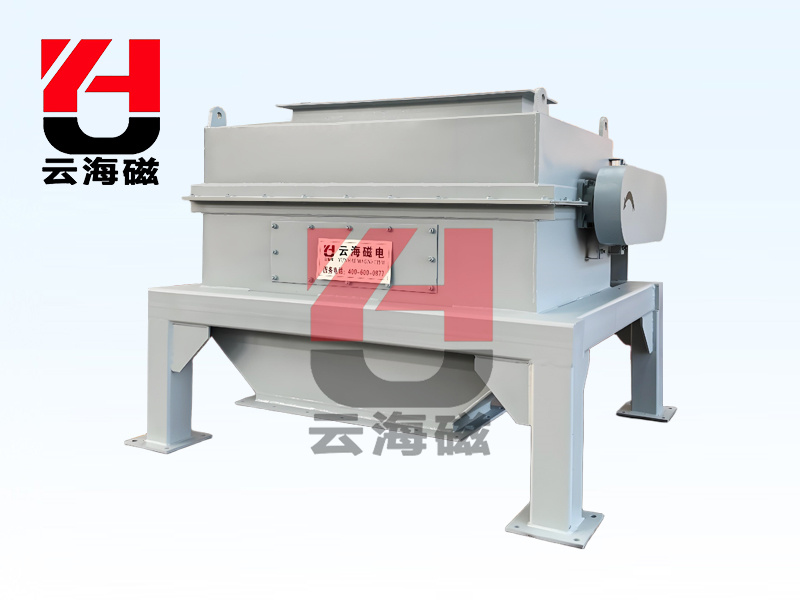

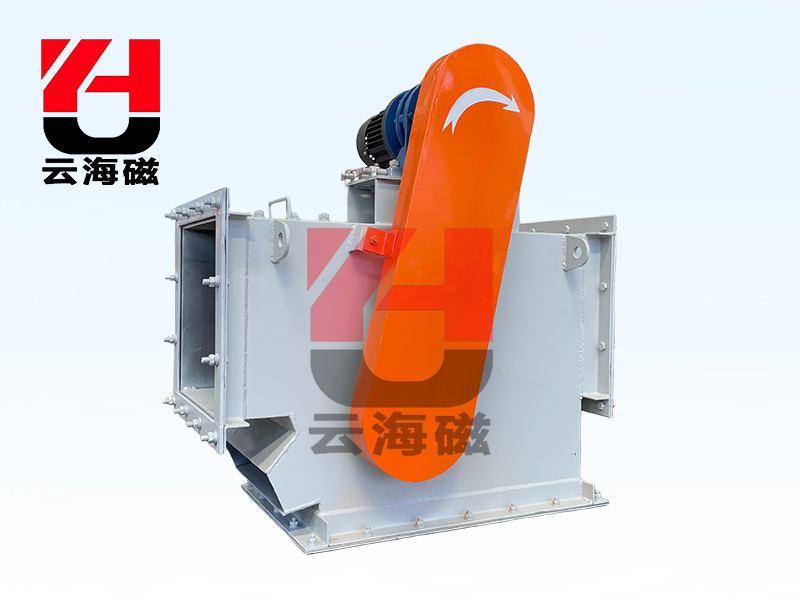

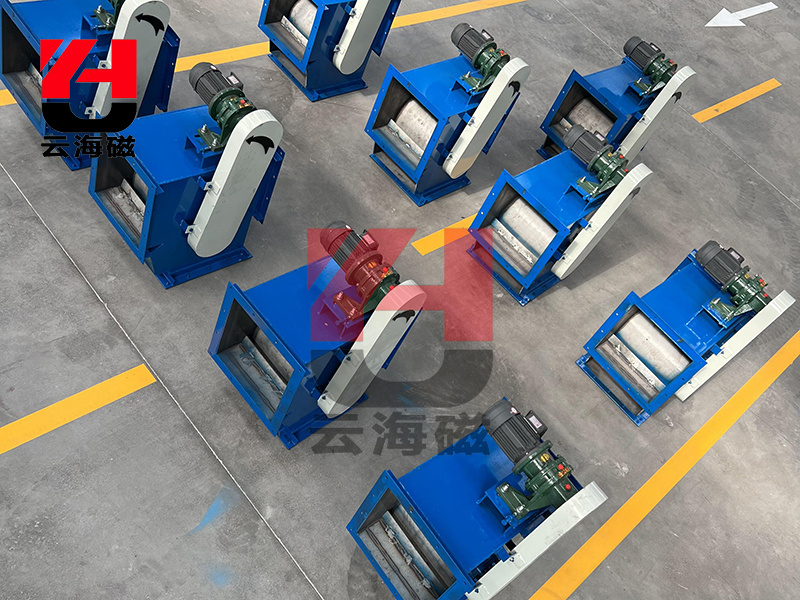

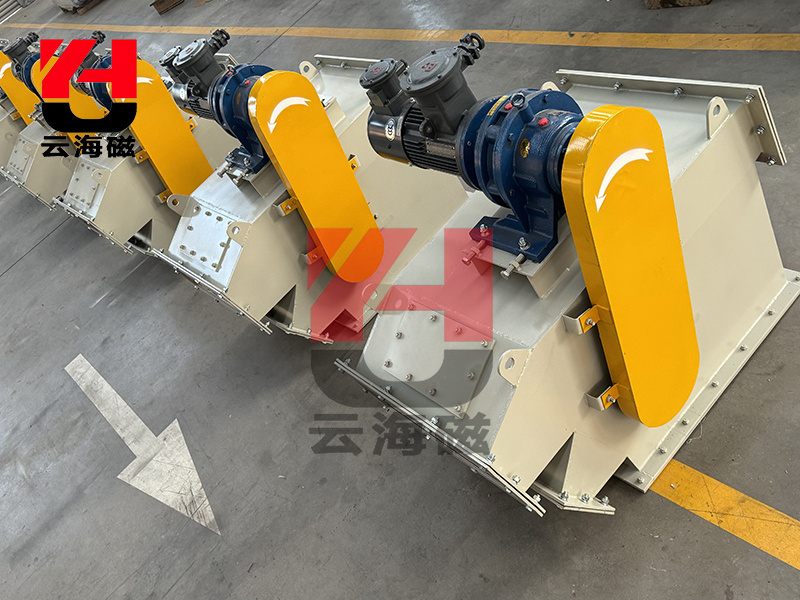

product image

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE