menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

RCYF series permanent magnet pipeline iron remover

RCYF series permanent magnet pipeline iron remover

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

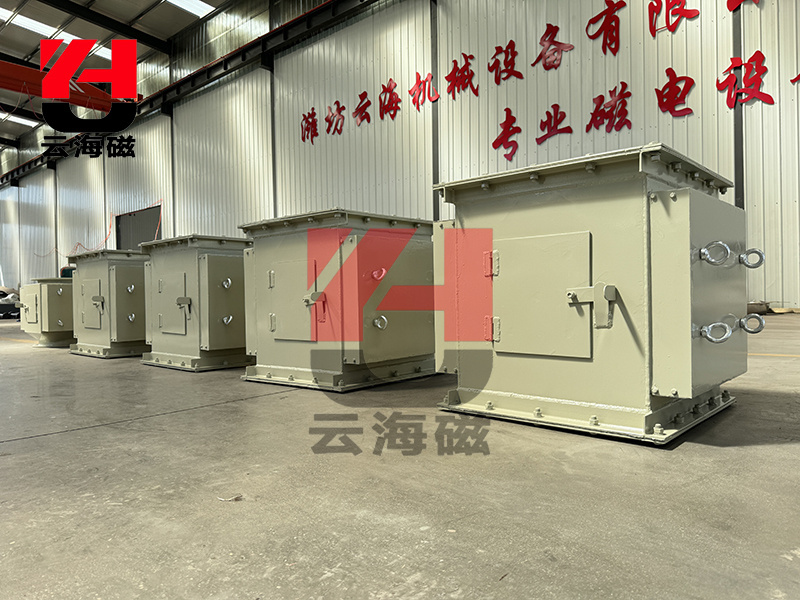

RCYF series permanent magnet pipeline iron remover

Product Introduction

The RCYF vertical pipeline permanent magnet iron remover uses high-performance permanent magnet neodymium iron boron material as the magnetic source, with strong magnetic field, strong suction force, high iron removal rate, maintenance free, energy-saving, safe and reliable use, and is suitable for different particle requirements. The product is widely used in industries such as cement, building materials, chemical industry, grain, feed, refractory materials, and chemical raw materials for removing iron from powdered, granular, and block materials. It can be connected to conveying pipelines and installed vertically for use.

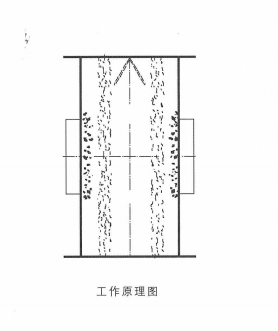

working principle

The RCYF pipeline type iron remover uses high-performance material Magneto neodymium iron boron as excitation, which has the characteristics of small size, light weight, strong magnetic field, clean iron removal, no energy consumption, easy operation, and long service life. When working, ferromagnetic substances in bulk materials are firmly adsorbed by the strong magnetic field of the iron remover. When removing ferromagnetic materials, simply open the dedicated iron removal door to clean them. This series of products is widely used for iron removal in powdered, granular, and block materials in industries such as cement, electricity, medicine, plastics, grain, food, ceramics, and building materials.

Technical Features

⑴ High performance strong magnetic material neodymium iron boron is used as the magnetic source, which has high temperature resistance, stable performance, and is not easily demagnetized.

The unique magnetic circuit design and dual pole structure greatly deepen the field strength of the magnetic field area through which the material passes, and the suction force is 2-3 times that of ordinary pipeline iron removers.

⑶ The pipeline has a fully sealed structure, and the iron remover is installed externally to avoid damage to the iron remover caused by long-term use.

⑷ Small size, light weight, vertically installed, easy to remove iron.

⑸ Design can be based on the user's site.

Installation requirements

1. During installation, there must be sufficient space for installation, operation, and unloading of the equipment.

2. After the iron remover is put into operation, the ferromagnetic substances adsorbed on the iron remover should be cleaned regularly according to the time. If not cleaned in time, it will affect the iron removal effect. During cleaning, simply stop the machine.

3. Simply connect the flanges at both ends.

4. Regularly check the condition of the magnetic separation surface to prevent jamming after entering large iron blocks

5. The temperature of the incoming material should not exceed 50 degrees, as excessive temperature will lower the magnetic field.

Technical Specifications

| Parameters/Project/Model | Adapt to yield T/h | Pipeline external dimensions mm | Dimensions of permanent magnets mm | Flange interface size mm | Adapt to slope | weight kg |

| RCYF-3 | 60 | 300×300×600 | 300×250×80 | 360×360 | 90° | 220 |

| RCYF-4 | 100 | 400×400×700 | 400×300×85 | 460×460 | 320 | |

| RCYF-5 | 200 | 500×500×800 | 500×400×85 | 600×600 | 460 | |

| RCYF-6 | 400 | 600×600×1000 | 600×450×180 | 700×700 | 820 | |

| RCYF-7 | 600 | 700×700×1200 | 700×500×210 | 840×840 | 1250 | |

| RCYF-8 | 800 | 800×800×1400 | 800×700×210 | 940×940 | 1460 | |

| RCYF-10 | 1000 | 1500×800×1500 | 1500×700×210 | 1640×940 | 2580 |

product image

on-site installation

location:

location: