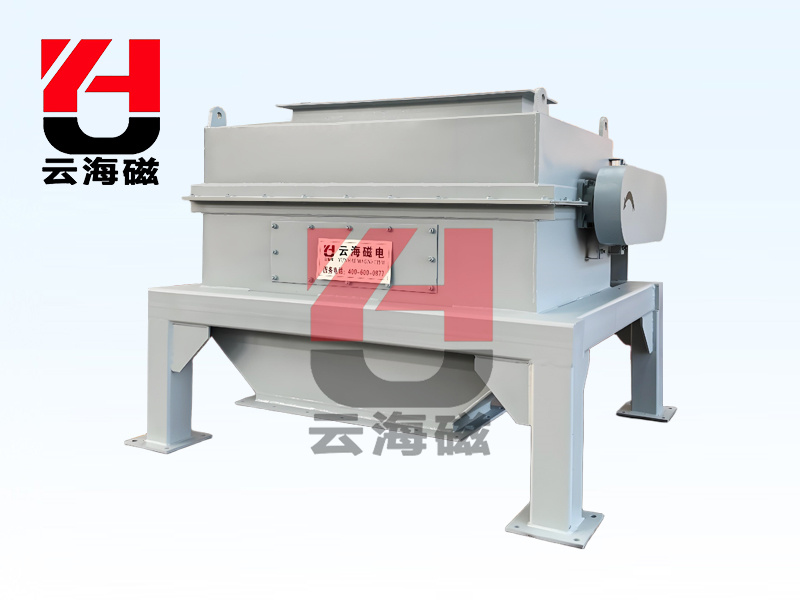

HS disc tailings recycling machine

Product Introduction

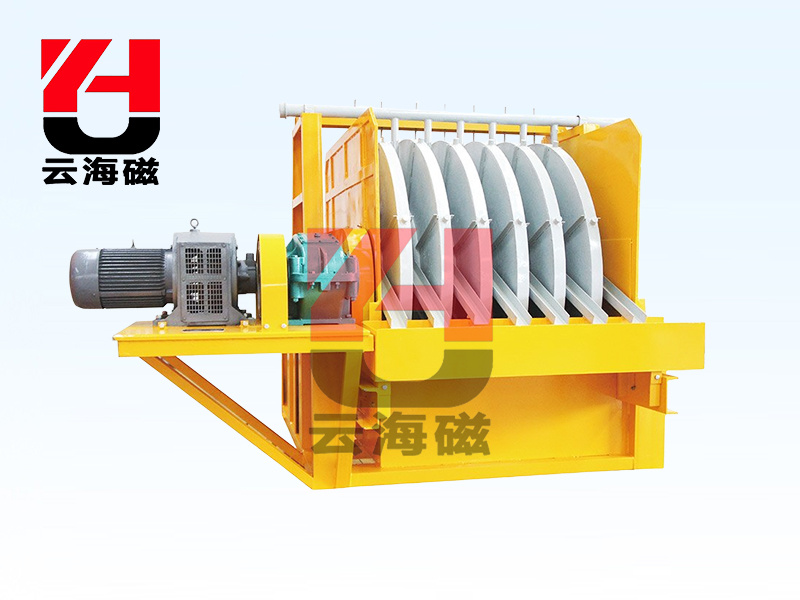

Disc tailings recycling is composed of five main parts: main machine, unloading device, ore collection tank, chute, and frame. The working principle is that the host disk is installed in a chute, and the slurry flows in from one end of the chute and passes through the gap between the disk and the disk. The magnetic minerals in the slurry are adsorbed on the surface of the disk, while the slurry of non-magnetic minerals flows out from the other end of the chute. The host roller rotates, and the magnetic minerals adsorbed on the surface of the disk are carried out of the slurry surface. When entering the unloading area, the unloading device inserted between the gaps of the disk and rotating throws the magnetic minerals adsorbed on the magnetic surface into the collection tank, which collects and outputs them.

Technical Features

1. Magnetic field layout: The magnetic pole spacing between disks is small, and there is no zero magnetic field between disks.

2. Unloading: Unloading is a non-contact forced unloading process, with a protective layer of mineral powder left on the surface of the disk. The disk surface is free of wear and tear, and the overall lifespan of the machine is 8-10 times that of conventional models. It also improves the grade of recovered magnetic minerals.

3. Large processing capacity: This machine is specially designed for tailings reselection, and its structure has the characteristics of processing high flow, low-grade tailings, which is several times or even more than ten times the processing capacity of existing drum magnetic separators.

4. High recovery rate: All materials passing between disks are subjected to the action of a magnetic field, and magnetic minerals are fully recovered, resulting in a high recovery rate.

5. Water saving: Due to the use of a unique magnetic field arrangement, magnetic minerals contain a large amount of water, and the unloaded minerals are in a flowing state, which can basically be done without adding water or with a small amount of supplementary water.

6. Energy saving: A disc type tailings recycling machine can process several times or even more than ten times the amount of other ordinary equipment, with an installed capacity of only a few kilowatts, so the energy-saving effect is significant.

7. Easy installation: The disc type tailings recycling machine has a large processing capacity, small footprint, and small difference in feed and discharge levels. It can be installed in places with tailings chutes.

8. High economic benefits: equipment investment is small, output benefits are high, and annual output benefits are generally several times or even more than ten times the equipment investment.

Technical Specifications

| model | specification | working area(m2) | power(kw) | host rotation speed(min) | Number of magnetic pole groups | surface field strength (MT) | processing capacity (T/h) |

| HS-8008 | 800×8 | 12 | 5.5 | 1 | 8 | 150 | 200 |

| HS-1008 | 1000×8 | 15 | 5.5 | 1 | 8 | 150 | 240 |

| HS-1508 | 1500×8 | 20 | 5.5 | 1 | 8 | 150 | 280 |

| HS-1510 | 1500×10 | 25 | 5.5 | 1 | 10 | 150 | 350 |

| HS-1512 | 1500×12 | 30 | 5.5 | 1 | 12 | 150 | 420 |

| HS-1608 | 1600×8 | 24 | 5.5 | 1 | 8 | 150 | 340 |

| HS-1610 | 1600×10 | 30 | 5.5 | 1 | 10 | 150 | 420 |

| HS-1612 | 1600×12 | 36 | 5.5 | 1 | 12 | 150 | 500 |

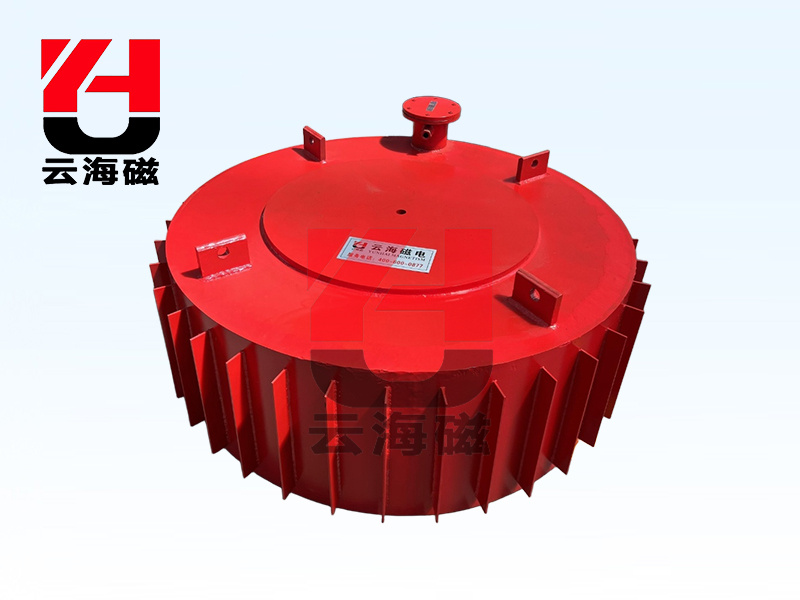

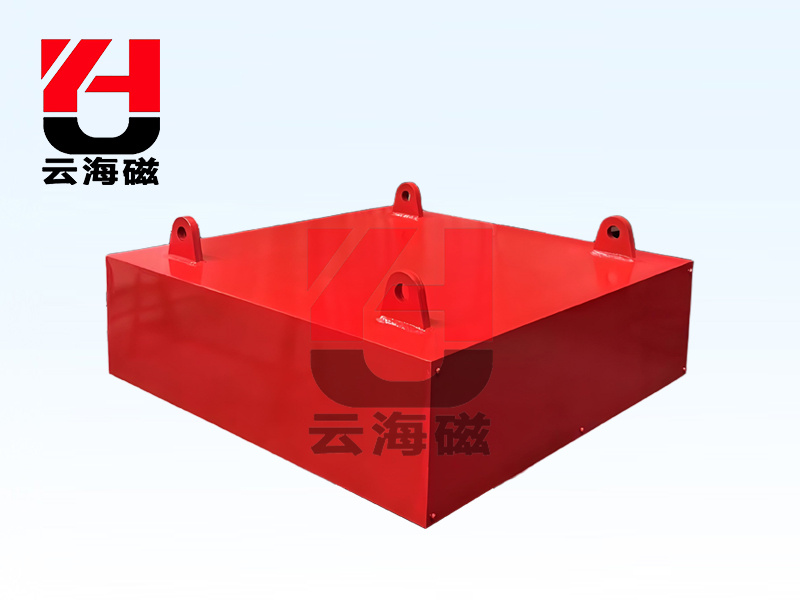

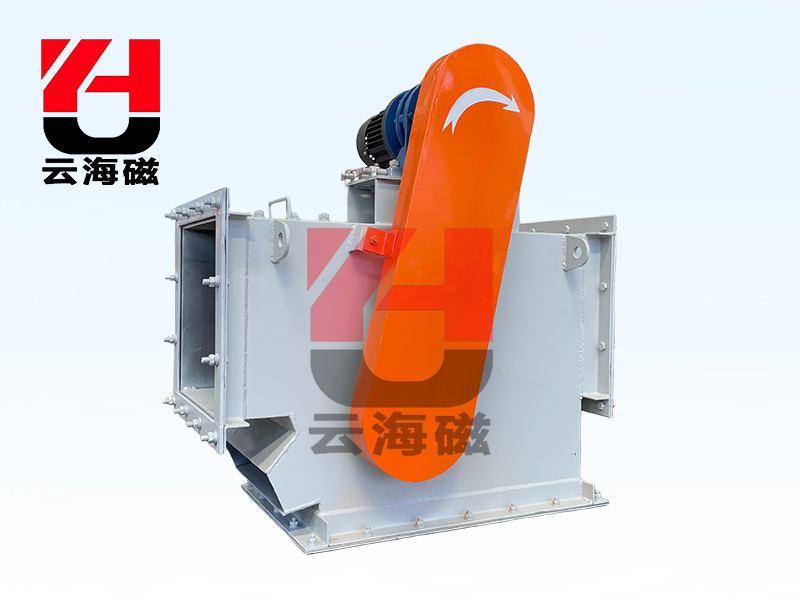

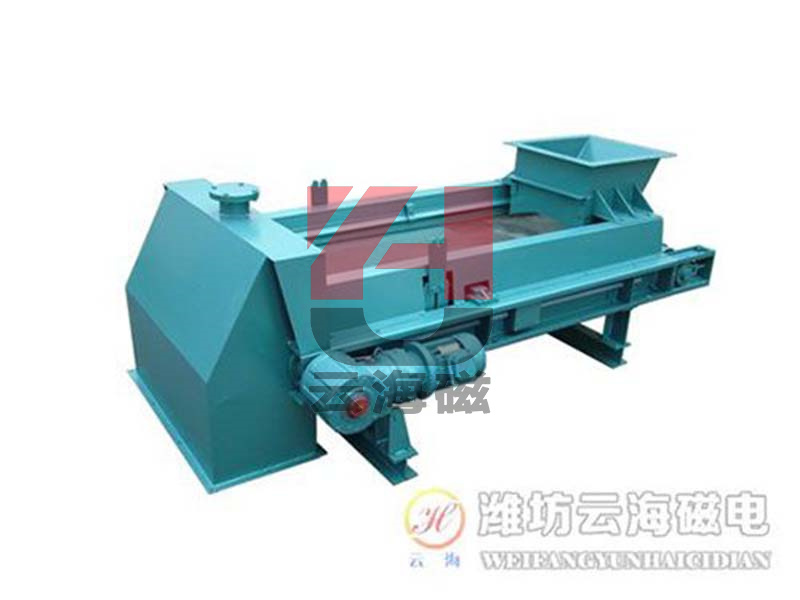

product image

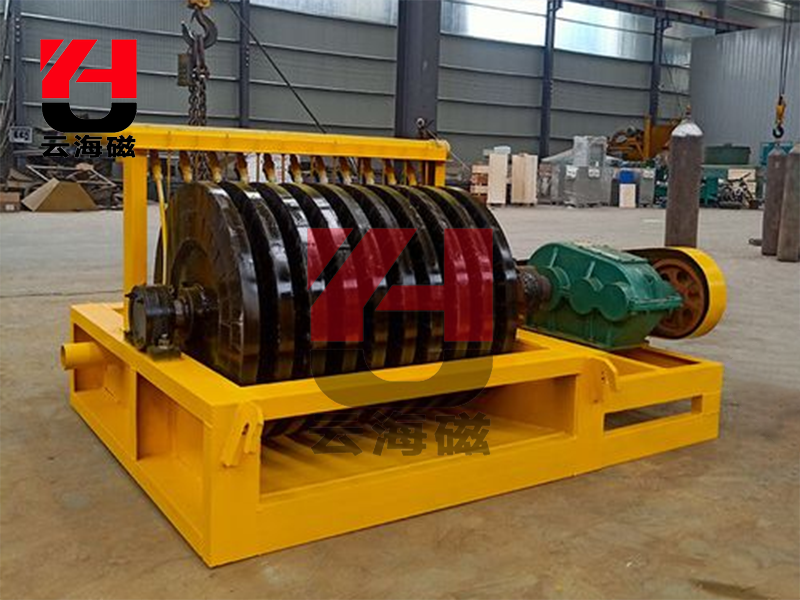

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE