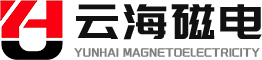

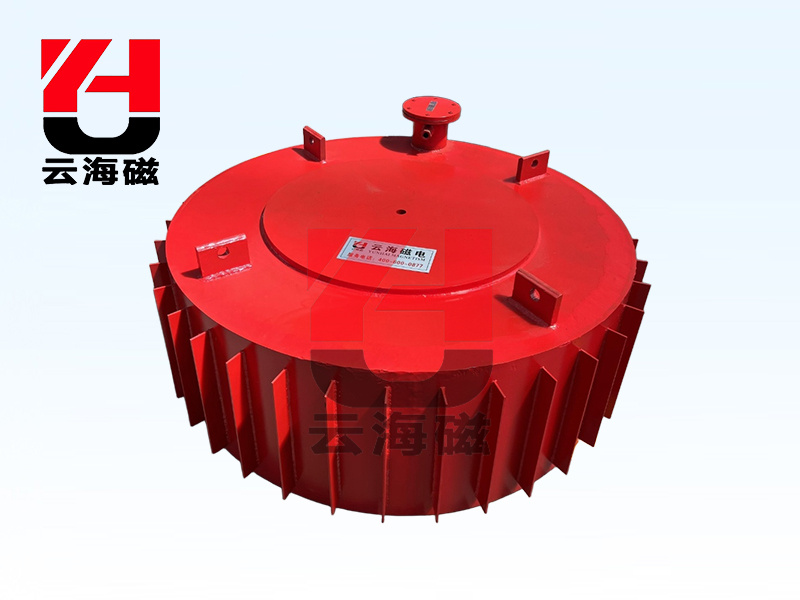

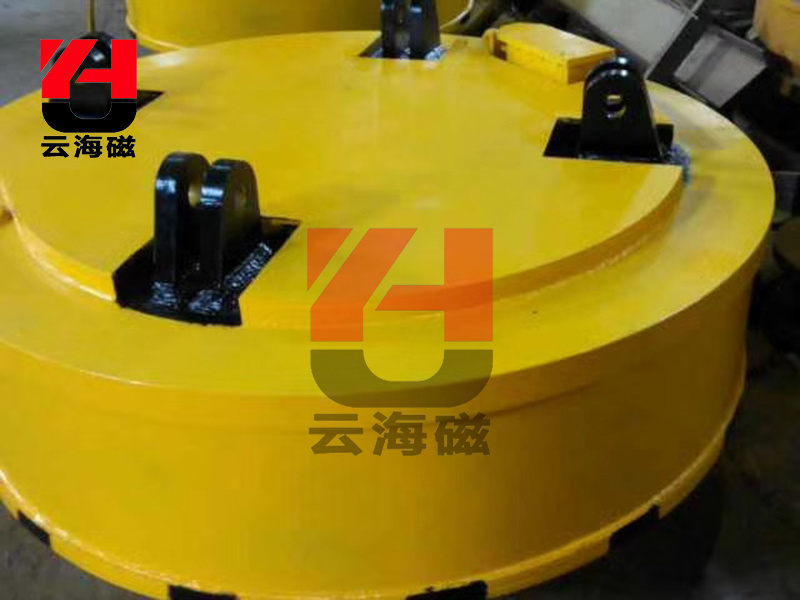

MW lifting electromagnet

Product Introduction

Suitable for transporting cast iron ingots, steel balls, and various scrap steels. The excitation methods can be: constant voltage method, strong magnetic method, and overexcitation method.

Technical Features

1. Fully enclosed structure: Adopting a fully sealed structure, it has good moisture resistance.

2. High suction power and low energy consumption: Through computer optimized design, the structure is reasonable, the weight is light, the suction power is high, and the energy consumption is low.

3. Long service life: The excitation coil has been treated with special technology to improve its electrical and mechanical properties. The insulation material has a heat resistance level of C and a long service life.

4. The rated power continuity rate of ordinary electromagnets has been increased from 50% to 60%, improving the efficiency of their use.

5. Energy saving: Usually using constant voltage control, strong excitation control (DC-290V/DC-220V) and constant current power supply can also be used. It can not only improve lifting capacity, but also save energy and increase economic benefits.

6. Easy installation, operation, and maintenance: The lifting electromagnet is easy to install, operate, and maintain.

Technical Specifications

| model | MW5-70L/1 | MW5-80L/1 | MW5-90L/1 | MW5-110L/1 | MW5-120L/1 | MW5-130L/1 | MW5-150L/1 | MW5-165L/1 | MW5-180L/1 | MW5-210L/1 | MW5-240L/1 |

Overall dimensions | A |

mm | 700 | 800 | 900 | 1100 | 1200 | 1300 | 1500 | 1650 | 1800 | 2100 | 2400 |

| B | 800 | 900 | 1090 | 1140 | 1150 | 1240 | 1250 | 1590 | 1490 | 1860 | 2020 |

| C | 160 | 160 | 200 | 220 | 220 | 250 | 350 | 370 | 370 | 400 | 450 |

| D | 90 | 90 | 125 | 150 | 150 | 175 | 210 | 230 | 230 | 250 | 280 |

| E | 30 | 30 | 40 | 50 | 45 | 60 | 60 | 75 | 75 | 80 | 90 |

| self-respect | kg | 500 | 620 | 810 | 1350 | 1700 | 2100 | 2800 | 3200 | 4200 | 7020 | 9000 |

| Cold current | A | 15.0 | 18 | 26.6 | 35 | 45.5 | 54 | 71.2 | 75 | 102.4 | 123 | 154 |

| Power consumption (cold state) |

| 3.3 | 3.96 | 5.86 | 7.7 | 10 | 11.9 | 15.6 | 15.6 | 22.5 | 27 | 33.6 |

| lifting capacity | Steel ball |

| 2500 | 3000 | 4500 | 6500 | 7500 | 8500 | 11000 | 12500 | 14500 | 21000 | 26000 |

| Cast iron ingot | 380/200 | 480/250 | 600/400 | 1000/800 | 1300/1000 | 1400/1100 | 1900/1500 | 2300/1800 | 2750/2100 | 3500/2800 | 4800/3800 |

| Cutting head | 380/200 | 480/250 | 600/400 | 1000/800 | 1300/1000 | 1400/1100 | 1900/1500 | 2300/1800 | 2750/2100 | 3500/2800 | 3500/2800 |

| Cast iron chips | 120/100 | 150/130 | 250/200 | 450/400 | 600/650 | 700/600 | 1100/900 | 1300/1100 | 1600/1350 | 2200/1850 | 2850/2300 |

| Equipment completeness | Cable connector | DL-102 | DL-202 |

| cable reel | JTA100-10-2 | JTA200-15-2 |

| Rectification control cabinet | STML-4E-C | STQL-7E-C | STQL-7E-C | STQL-9E-C | STQL-14E-C | STQL-14E-C | STQL-19E-C | STQL-19E-C | STQL-25E-C | STQL-32E-C | STQL-38E-C |

product image

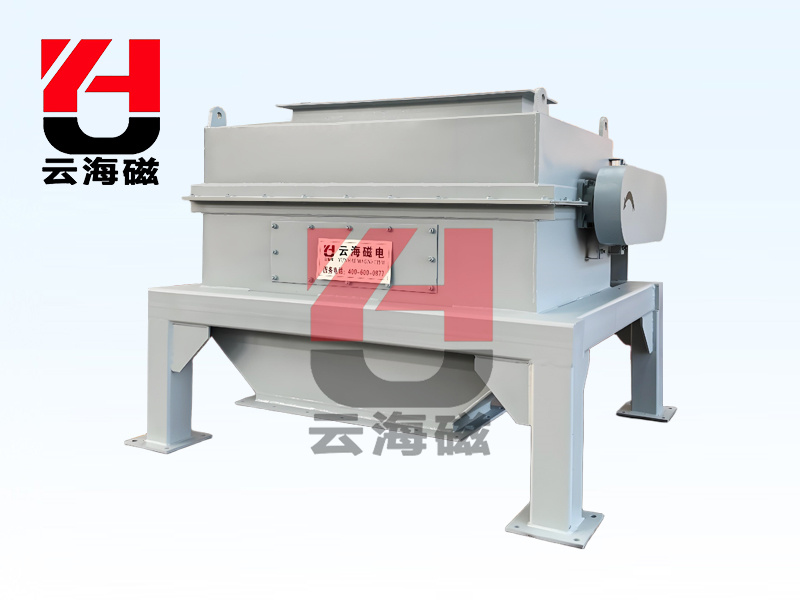

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE