咨询电话:400-600-0877

咨询电话:400-600-0877

CTB (N, S) series permanent magnet wet magnetic separator

CTB (N, S) series permanent magnet wet magnetic separator

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

CTB (N, S) series permanent magnet wet magnetic separator

Product Introduction

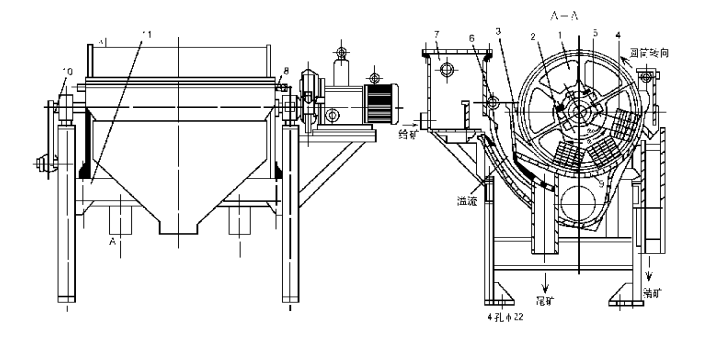

CTB/CTS/CTN permanent magnet drum magnetic separator is suitable for mining, coal preparation plants and other units, used for weak magnetic field wet selection of fine particles of strong magnetic minerals, or removal of mixed strong magnetic minerals in non-magnetic minerals.

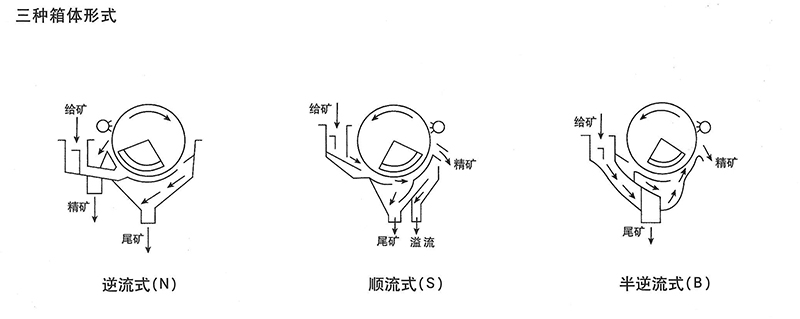

This machine has three types of tanks: semi counter current tank (CTB), counter current tank (CTS), and counter current tank (CTN), which are suitable for different particle sizes and process requirements. The magnetic circuit of the machine is reasonable, and high coercivity and high remanence permanent magnets are strictly selected to ensure that the magnetism does not decrease over a long period of time, safeguarding the long-term interests of users. The overall structure is reliable and durable.

working principle

▲ Adopting rare earth composite magnetic system, advanced technology and reasonable structure. Through special design, the magnetic field intensity distribution in the selected and scanned areas is more reasonable, and the sorting effect is more obvious.

The tank has been specially designed to prevent material blockage and leakage.

▲ Wear resistant aluminum flanges are used at both ends of the cylinder; The surface of the drum is lined with wear-resistant materials, which have good wear resistance and long service life.

▲ Adopting a cycloidal reducer, it has small size, light weight, and low power consumption.

▲ Simple structure, large processing capacity, easy operation, and easy maintenance.

Technical Specifications

| model | Cylindrical ruler mm | Magnetic induction intensity on the surface of the cylinder | Processing ability | Motor power | Cylinder rotation speed r/min | weight kg | |||

| average | Scan the selection area | Midfield strong magnetic field | t/h | m3/h | |||||

| CTB-44 | 400×400 | 130 | 180 | 250-400 | 1-2 | 4-5 | 1.1 | 45 | 350 |

| CTB-46 | 400×600 | 130 | 180 | 250-400 | 2-3 | 5-10 | 1.1 | 45 | 600 |

| CTB-63 | 400×300 | 140 | 180 | 250-400 | 3-5 | 8-15 | 1.1 | 40 | 600 |

| CTB-66 | 400×600 | 140 | 180 | 250-400 | 5-10 | 10-30 | 1.1 | 40 | 750 |

| CTB-69 | 600×900 | 180 | 180 | 250-400 | 8-15 | 20-50 | 1.1 | 40 | 910 |

| CTB-612 | 600×1200 | 140 | 180 | 250-400 | 10-20 | 25-60 | 2.2 | 40 | 1050 |

| CTB-618 | 600×1800 | 140 | 180 | 250-400 | 15-30 | 40-80 | 2.2 | 40 | 1340 |

| CTB-712 | 750×1200 | 160 | 200 | 300-500 | 15-30 | 40-80 | 3 | 35 | 1500 |

| CTB-718 | 750×1800 | 160 | 200 | 300-500 | 20-45 | 60-100 | 3 | 35 | 2100 |

| CTB-918 | 900×1800 | 170 | 200 | 300-600 | 25-55 | 70-120 | 4 | 28 | 2900 |

| CTB-924 | 900×2400 | 170 | 200 | 300-600 | 35-70 | 80-130 | 4 | 28 | 3600 |

| CTB-1018 | 1050×1800 | 180 | 220 | 300-700 | 40-75 | 110-160 | 5.5 | 22 | 4000 |

| CTB-1021 | 1050×2100 | 180 | 220 | 300-700 | 50-100 | 140-200 | 5.5 | 22 | 4500 |

| CTB-1024 | 1050×2400 | 180 | 220 | 300-700 | 60-120 | 170-260 | 5.5 | 22 | 5000 |

| CTB-1030 | 1050×3000 | 180 | 220 | 300-700 | 70-150 | 200-320 | 7.5 | 22 | 6300 |

| CTB-121 | 1200×1800 | 180 | 220 | 300-700 | 60-110 | 150-230 | 5.5 | 19 | 4900 |

| CTB-1224 | 1200×2400 | 180 | 220 | 300-700 | 70-130 | 80-300 | 7.5 | 19 | 5900 |

| CTB-1230 | 1200×3000 | 180 | 220 | 300-700 | 80-160 | 250-400 | 7.5 | 19 | 7200 |

| CTB-1530 | 1500×3000 | 180 | 220 | 300-700 | 100-180 | 290-480 | 11 | 14 | 8900 |

| CTB-1540 | 1500×4000 | 180 | 220 | 300-700 | 115-220 | 300-540 | 11 | 14 | 9900 |

product image

on-site installation

location:

location: