menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

RCYK armored permanent magnet self dumping iron remover

RCYK armored permanent magnet self dumping iron remover

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

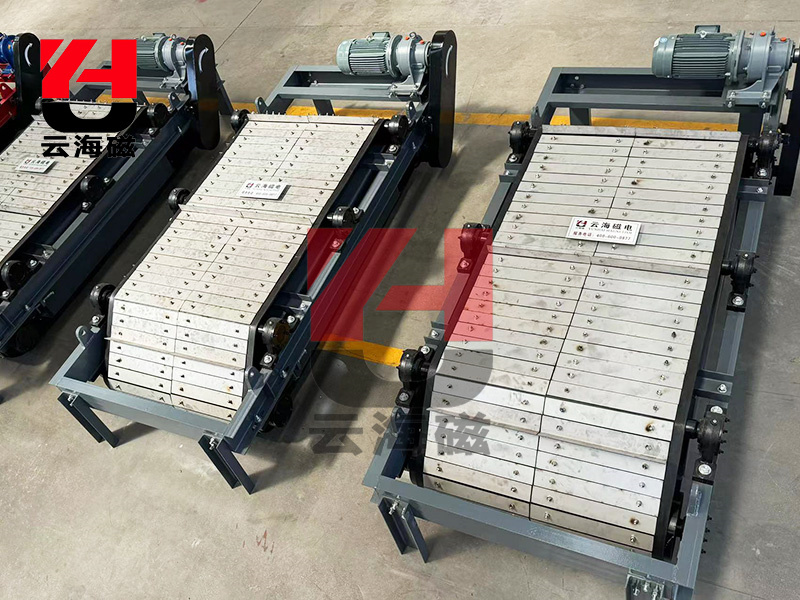

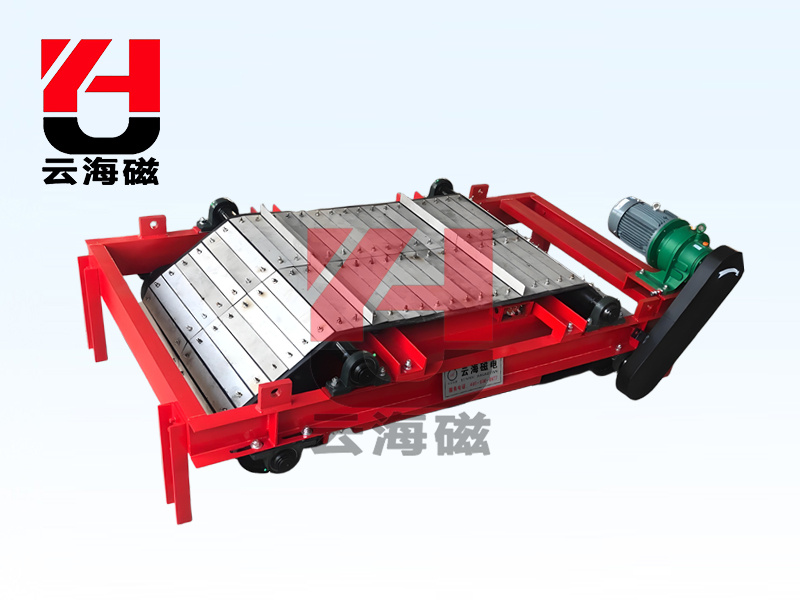

RCYK armored permanent magnet self dumping iron remover

Product Introduction

The RCYK armored magnetic tape iron remover series is specifically designed for iron selection in metallurgical slag, direct reduction iron plants, slag stewing workshops, casting workshops, etc. It has a unique armored belt design that can effectively prevent sharp ferromagnetic debris from damaging the belt. The magnetic system uses rare earth neodymium iron boron permanent magnet material as the magnetic source, and the magnetic performance is stable and reliable; It has high magnetic field strength, large gradient, strong suction force, no need for electric excitation, energy-saving, automatic iron unloading, and easy operation. Armored belts have automatic correction function, suitable for working in harsh environmental conditions, and can operate safely without faults for a long time.

RCYK armored magnetic tape iron remover specifications are safe: there are three types that comply with the national standard: ordinary type, super strong type higher than the national standard, and explosion-proof type.

Technical Features

1. The RCYK series armored permanent magnet self removing iron device is mainly used for iron removal operations in harsh environments such as steel slag, waste incineration power generation, and casting plants with high iron content and high temperature. The work intensity is high, and the dependence on iron removal equipment is very high.

The circular belt of RCYK armored permanent magnet self removing iron device must use 304 stainless steel as the protective plate, which can increase the service life of the belt.

3. Due to the production environment similar to steel slag, ferromagnetic objects can sometimes weigh up to hundreds of kilograms, and many materials have a high slag content, lower magnetic susceptibility than ordinary iron parts, making them more difficult to select. Therefore, the magnetic field must be strengthened.

4. The fixing bolts for RCYK armored permanent magnet self removable iron armor must be customized bolts to prevent the armor from falling off the ring belt when subjected to external impact or scratching, reducing the iron removal effect and service life.

Technical Specifications

| Parameters/Project/Model | Adaptive bandwidth mm | Rated suspension height mm | Magnetic induction intensity at rated height ≥ mT | Adapt to belt speed m/s | Iron absorption capacity | working system | Drive motor power | Dimensions mm | Weight kg | ||||||

| A | B | C | D | E | F | ||||||||||

| RCYK-5 | 500 | 150 | 60 | ≤4.5 | kg 0.1-35 | continuous | 1.5 | 1900 | 735 | 935 | 950 | 753 | 451 | 850 | |

| RCYK-6.5 | 650 | 200 | 70 | 2.2 | 2050 | 780 | 1030 | 1100 | 753 | 451 | 1300 | ||||

| RCYK-8 | 800 | 250 | 70 | 2.2 | 2290 | 796 | 1280 | 1300 | 1088 | 451 | 1580 | ||||

| RCYK-10 | 1000 | 300 | 70 | 3.0 | 2660 | 920 | 1550 | 1400 | 1335 | 451 | 2120 | ||||

| RCYK-12 | 1200 | 350 | 70 | 4.0 | 2900 | 970 | 1720 | 1550 | 1515 | 516 | 2980 | ||||

| RCYK-14 | 1400 | 400 | 70 | 4.0 | 3225 | 1050 | 1980 | 1800 | 1755 | 516 | 4100 | ||||

| RCYK Super Series: | |||||||||||||||

| RCYK-6.5 | T1 | 650 | 200 | 90 | ≤4.5 | 0.1-50 | continuous | 2.2 | 2160 | 1075 | 795 | 1200 | 890 | 451 | 1300 |

| T2 | 120 | 2.2 | 2160 | 1200 | 890 | 1420 | |||||||||

| T3 | 150 | 2.2 | 2310 | 1300 | 890 | 1750 | |||||||||

| RCYK-8 | T1 | 800 | 250 | 90 | 2.2 | 2350 | 1280 | 795 | 1300 | 1090 | 451 | 1920 | |||

| T2 | 120 | 2.2 | 2350 | 1300 | 1090 | 2180 | |||||||||

| T3 | 150 | 3.0 | 2520 | 1400 | 1090 | 2820 | |||||||||

| RCYK-10 | T1 | 1000 | 300 | 90 | 3.0 | 2660 | 1540 | 950 | 1400 | 1335 | 451 | 2350 | |||

| T2 | 120 | 3.0 | 2660 | 1400 | 1335 | 2700 | |||||||||

| T3 | 150 | 4.0 | 2760 | 1400 | 1335 | 3680 | |||||||||

| RCYK-12 | T1 | 1200 | 350 | 90 | 4.0 | 2900 | 1730 | 970 | 1600 | 1515 | 516 | 3250 | |||

| T2 | 120 | 4.0 | 2900 | 1600 | 1515 | 4100 | |||||||||

| T3 | 150 | 5.5 | 2900 | 1600 | 1515 | 5150 | |||||||||

| RCYK-14 | T1 | 1400 | 400 | 90 | 4.0 | 3225 | 1980 | 1180 | 1900 | 1750 | 516 | 4800 | |||

| T2 | 120 | 5.5 | 3225 | 1900 | 1750 | 5620 | |||||||||

| T3 | 150 | 5.5 | 3340 | 1900 | 1750 | 7450 | |||||||||

Note: All models in this series have reinforced T1, T2, and T3 product designs that are higher than the national standard. The rated magnetic field strength at the lifting height is 90mT, 120mT, and 150mT, respectively, and can be customized according to customer requirements.

product image

on-site installation

location:

location: