咨询电话:400-600-0877

咨询电话:400-600-0877

CBM series self-cleaning pipeline magnetic rod iron remover

CBM series self-cleaning pipeline magnetic rod iron remover

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

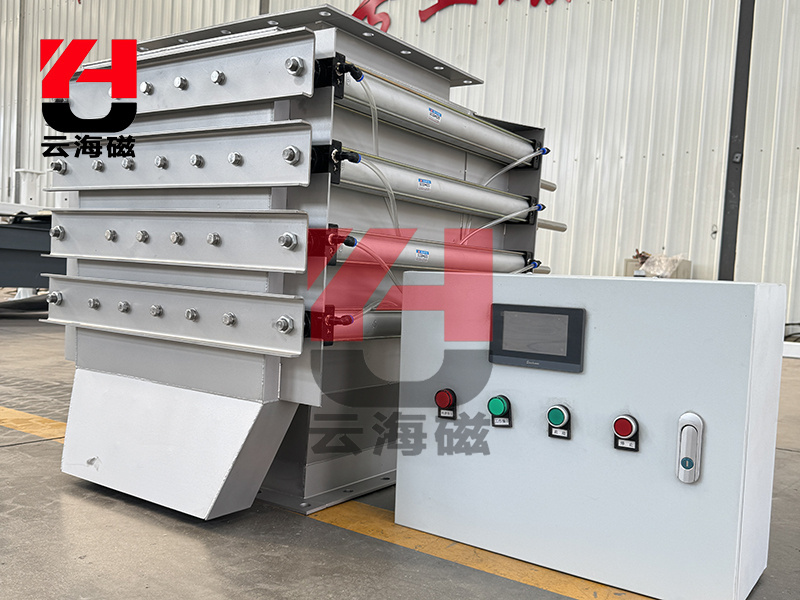

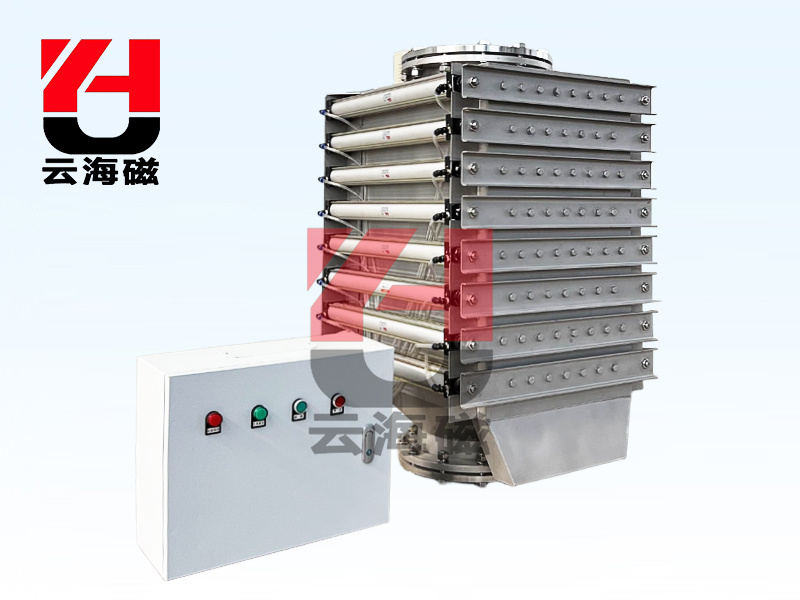

CBM series self-cleaning pipeline magnetic rod iron remover

Product Introduction

The CBM series self-cleaning pipeline magnetic rod iron remover is installed in the assembly line to achieve online real-time automatic removal of iron from materials. The automatic timing controller can be set for continuous automatic real-time cleaning, or the cleaning time can be set according to the iron content. Its powerful magnetic field can remove ferromagnetic substances from flowing, dry, highly mobile, powdery, and fine particles. It is mainly used for iron removal in industries such as food, chemical, pharmaceutical, quartz sand, potassium feldspar, carbon black, activated carbon, and fly ash.

working principle

The CBM series self-cleaning pipeline magnetic rod iron remover is mainly used to separate iron impurities in fine powder materials. It is arranged in a staggered manner with at least two layers of magnetic rods, ensuring that the material can fully contact the magnetic rods during the falling process. It can be set as a continuous alternating unloading of iron, so that when the first layer is extracted for unloading iron, other iron impurities that are still falling can be adsorbed. The cleaning of this equipment is fully automated, with a fully sealed structural design that ensures no pollution during the iron unloading process, allowing the entire operation and unloading work to be carried out in a sealed state. The magnetic rod shuttles back and forth in the sealed space, and the strong magnetic force can automatically remove the adsorbed iron impurities according to the set trajectory to the cleaning area. Fully sealed iron impurity collection port, quick opening and cleaning, saving time, effort and trouble.

Product Parameters

| model | feed inlet | material | Magnetic rod specifications | Drawer Layers | processing capacity | power supply |

| CBM-200 | DN200 | SUS304/316 | Φ25-Φ32可选 | 3 | 1t | 220V/380V |

| CBM-250 | DN250 | SUS304/316 | Φ25-Φ32可选 | 4 | 2-3t | 220V/380V |

| CBM-300 | DN300 | SUS304/316 | Φ25-Φ32可选 | 6 | 3-5t | 220V/380V |

| CBM-400 | DN400 | SUS304/316 | Φ25-Φ32可选 | 8 | 10t | 220V/380V |

The specific size can be customized according to the customer's on-site situation, production volume, and material temperature

product image

location:

location: