menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

CTZ semi magnetic drum

CTZ semi magnetic drum

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

CTZ semi magnetic drum

Product Introduction

The CTZ series permanent magnet semi magnetic drum is commonly used for purifying powdered, granular, and small block materials. It plays a reliable protective role in preventing damage and wear of crushers, grinders, and presses. It is easy to install, has strong suction, consumes no energy, works continuously, and is easy to operate. It can meet the requirements of users for high magnetic fields and deep iron removal.

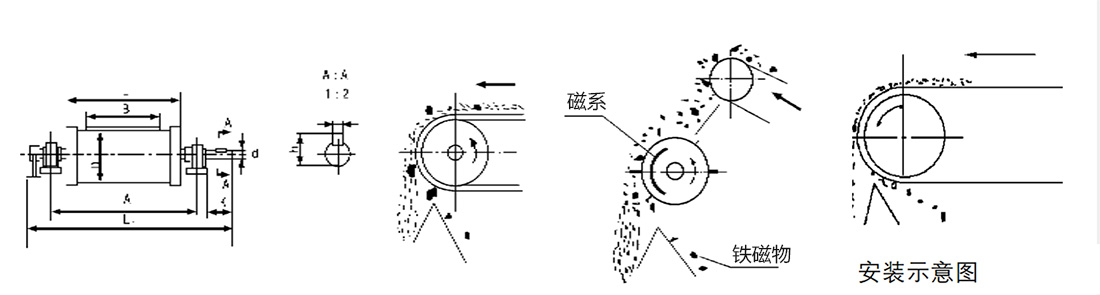

working principle

1. The material is transported to the feed inlet of the semi magnetic drum and evenly distributed on the surface of the drum.

During the movement of the drum, the magnetic drum will generate a strong magnetic field, which can adsorb materials with certain magnetism.

3. Inside the magnetic drum, the magnetic material will be attracted by magnetic force and adsorbed onto the surface of the drum along the direction of its movement.

4. Non magnetic materials are not affected by magnetic forces and are unloaded and discharged from the surface of the drum along the direction of its movement.

When the drum moves to the conveying position, the magnetic material will be conveyed to the discharge port for collection.

6. The discharged magnetic material can be controlled by adjusting the magnetic field strength of the semi magnetic drum and the drum.

Technical Specifications

| Project/Parameters/Model | Cylinder diameter mm | Adapt to bandwidth mm | Tube length mm | Magnetic induction intensity of cylinder surface ≈ Gs | Cylinder rotation speed r/min | Powder material with iron powder removal ≈ T/h | Removal of iron impurities from block materials ≈ T/h | Weight kg | Dimensions mm | |||||

| A | L1 | K | φd | h | b | |||||||||

| CTZ-32/40 | 320 | 400 | 500 | 3000 | 20-30 | 0.8 | 10 | 120 | 728 | 1010 | 100 | 50 | 53.5 | 14 |

| CTZ-32/50 | 320 | 500 | 600 | 3000 | 1 | 15 | 150 | 850 | 1115 | 115 | 50 | 53.5 | 14 | |

| CTZ-40/50 | 400 | 500 | 600 | 3000 | 2 | 20 | 240 | 850 | 1115 | 115 | 55 | 60 | 16 | |

| CTZ-50/50 | 500 | 500 | 600 | 3000 | 3.5 | 30 | 360 | |||||||

| CTZ-32/65 | 320 | 650 | 750 | 3000 | 2 | 20 | 210 | 1000 | 1350 | 135 | ||||

| CTZ-40/65 | 400 | 650 | 750 | 3000 | 2.8 | 30 | 350 | 1000 | 1350 | 135 | ||||

| CTZ-50/65 | 500 | 650 | 3000 | 4.5 | 40 | 420 | 60 | 64 | 18 | |||||

| CTZ-63/65 | 630 | 650 | 3000 | 7 | 45 | 830 | 90 | 97 | 24 | |||||

| CTZ-40/80 | 400 | 800 | 950 | 3000 | 8 | 55 | 470 | 1300 | 1630 | 175 | 70 | 76 | 20 | |

| CTZ-50/80 | 500 | 800 | 3000 | 10 | 65 | 600 | ||||||||

| CTZ-63/80 | 630 | 800 | 3000 | 10 | 80 | 800 | 1730 | |||||||

| CTZ-80/80 | 800 | 800 | 4000 | 12 | 100 | 1180 | 90 | 97 | 24 | |||||

| CTZ-63/100 | 630 | 1000 | 1150 | 3500 | 12 | 120 | 1300 | |||||||

| CTZ-80/100 | 800 | 1000 | 1150 | 4000 | 15 | 140 | 1800 | 1500 | 2000 | 215 | 110 | 119 | 32 | |

| CTZ-100/120 | 1000 | 1200 | 1400 | 4000 | 20 | 180 | 3100 | 1750 | 2270 | 255 | 130 | 140 | 36 | |

| CTZ-125/140 | 1250 | 1400 | 1600 | 4000 | 30 | 250 | 4800 | 2000 | 2555 | 275 | 150 | 161 | 40 | |

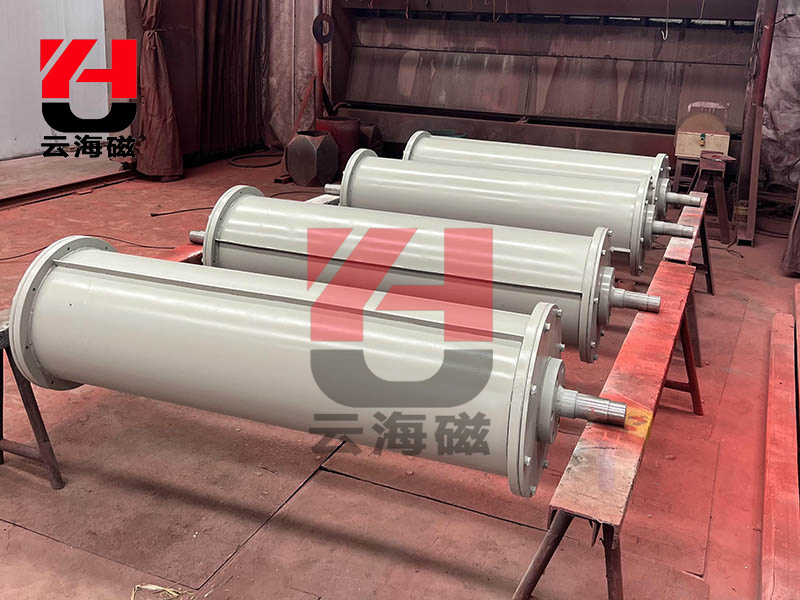

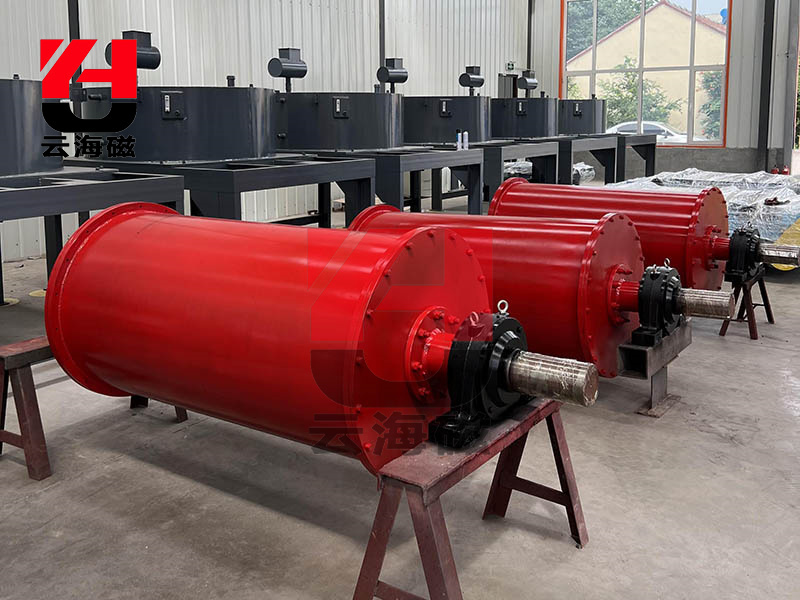

product image

on-site installation

location:

location: