Iron remover for slurry pipeline

Product Introduction

Slurry pipeline iron remover, also known as magnetic fluid iron remover or magnetic fluid filter, is used in fluid, semi fluid and other fluid materials with different viscosities to remove iron impurities and other ferromagnetic particles, keep the materials clean, and protect downstream production equipment.

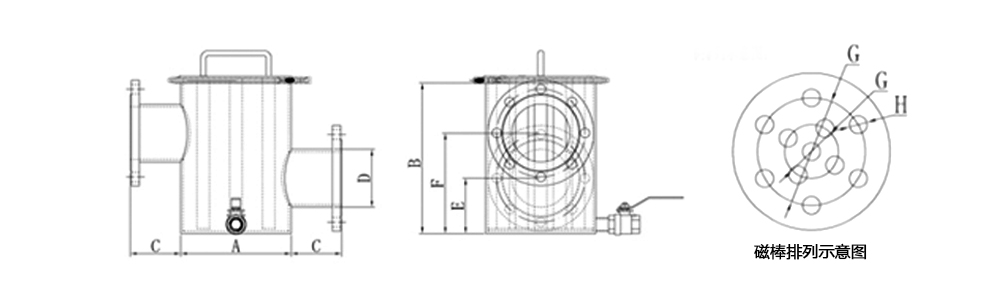

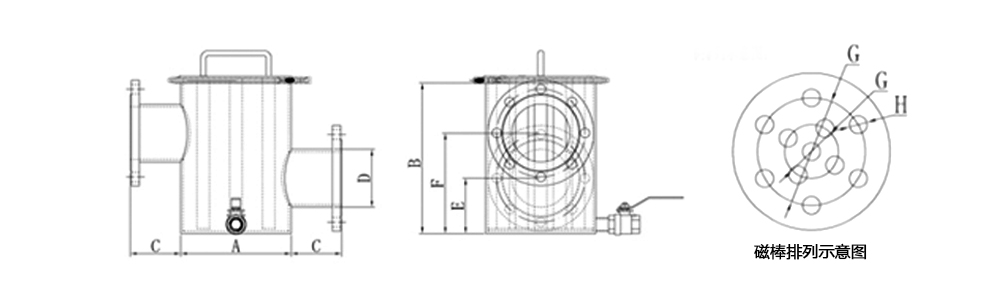

外形尺寸图

Technical Features

This product uses rare earth alloy neodymium iron boron as the magnetic source, with a long service life, no energy consumption, simple structure, convenient use, and a fully grid arranged magnetic system, which fully utilizes the strong magnetic area. The multi-layer design and layer by layer filtration make the iron removal more thorough and the effect more significant. The specifications and styles can be customized according to customer requirements and on-site conditions.

working principle

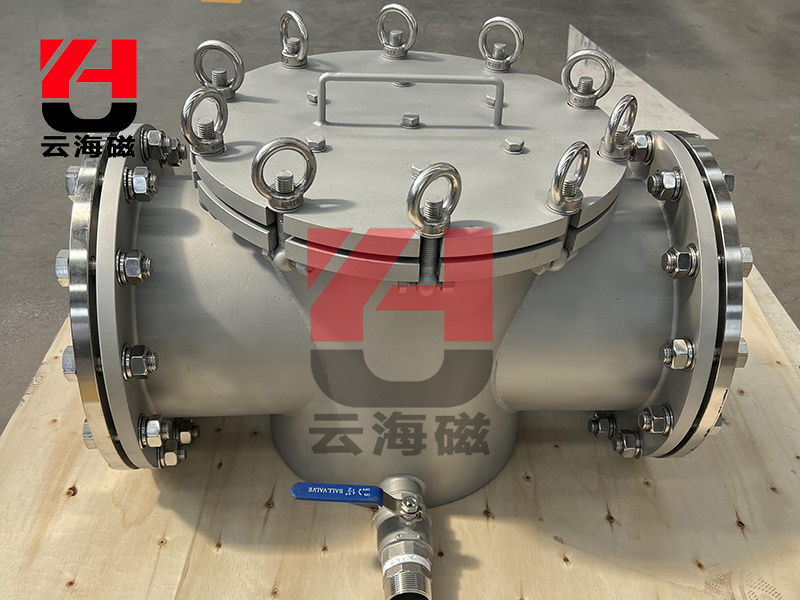

The pipeline type slurry iron remover (slurry iron remover) is a magnetic rod (magnetic rod) made of excellent seamless stainless steel pipe and high B-value rare earth alloy neodymium iron boron, and made by a special manufacturing method. It is installed in the body composed of excellent seamless stainless steel pipe and installed in the production line conveying pipeline or discharge port with a flange. When the liquid or slurry containing iron passes through, it is attracted by the magnetic rod and firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the safety of the product.

Scope of Application

Pipeline type slurry iron remover (slurry iron remover) is mainly used to remove ferromagnetic impurities in liquids and slurries. Widely applicable to industries such as ceramics, electricity, mining, plastics, chemicals, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy, etc.

Technical Specifications

| Product Number | Flange model | A | B | C | D | E | F | G | H | Total number of magnetic bars |

| CBX-32 | DN32 | Φ159 | 230 | 80 | Φ39 | 85 | 150 | Φ110 | Φ25 | 5 |

| CBX-40 | DN40 | Φ46 |

|

|

| Φ25 |

| CBX-50 | DN50 | Φ59 | Φ25 |

| CBX-65 | DN65 | Φ219 | 300 | 100 | Φ78 | 115 | 190 | Φ150 | Φ25 | 7 |

| CBX-80 | DN80 | Φ91 |

|

|

| Φ25 | 9 |

| CBX-100 | DN100 | Φ110 | Φ25 |

| CBX-125 | DN125 | Φ273 | 330 | 100 | Φ135 | 135 | 195 | Φ200 | Φ25 | 10 |

| CBX-150 | DN150 | Φ161 | 165 | 165 | Φ25 |

| CBX-200 | DN200 | Φ325 | 360 | 114 | Φ222 | 180 | 180 | Φ250 | Φ25 | 13 |

| CBX-250 | DN250 | Φ377 | 420 | 116 | Φ276 | 210 | 210 | Φ300 | Φ25 | 15 |

| CBX-300 | DN300 | Φ426 | 460 | 118 | Φ328 | 230 | 230 | Φ340 | Φ25 | 17 |

| CBX-350 | DN350 | Φ480 | 510 | 120 | Φ381 | 255 | 255 | Φ380 | Φ25 | 19 |

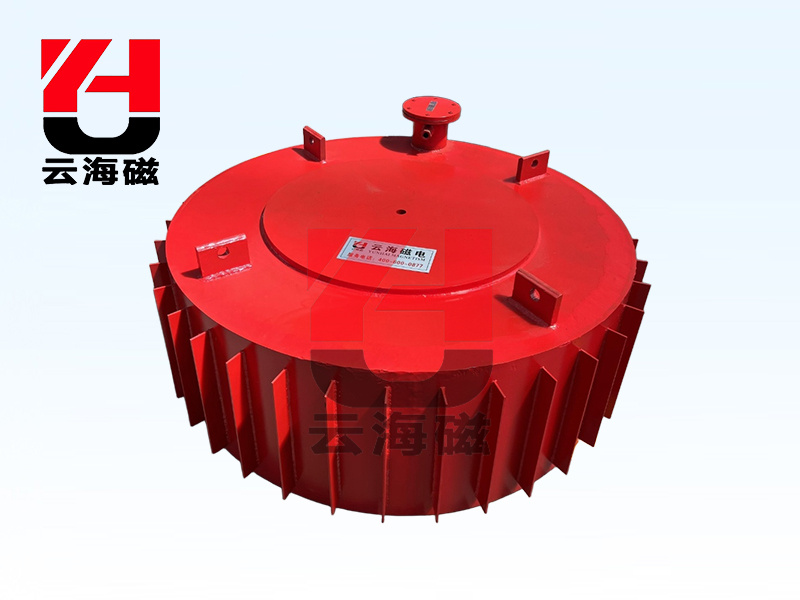

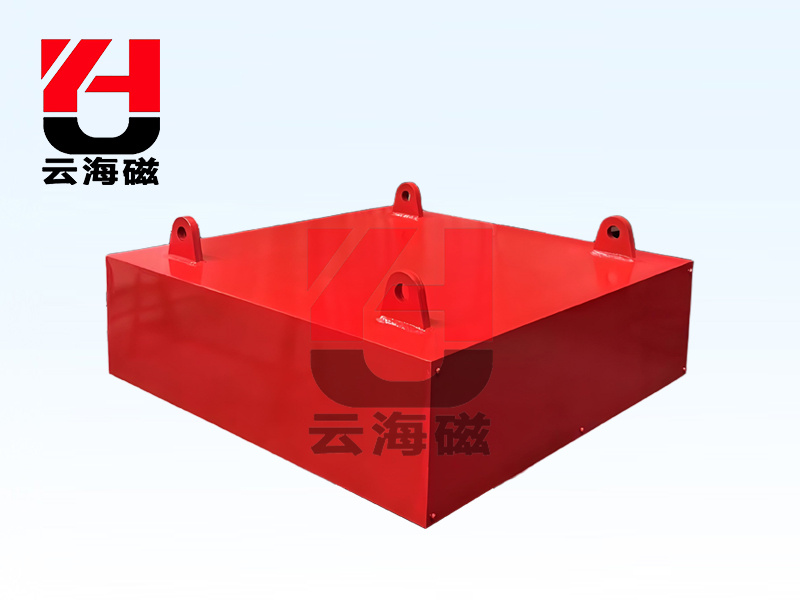

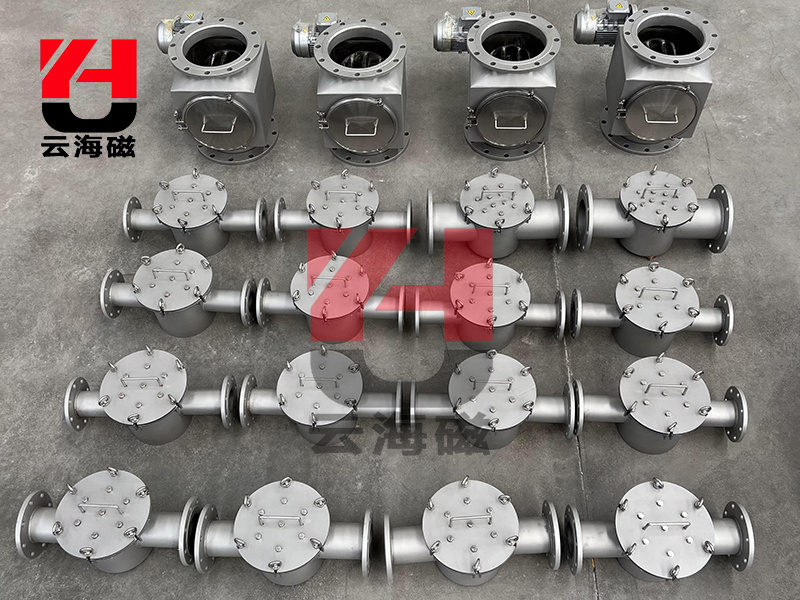

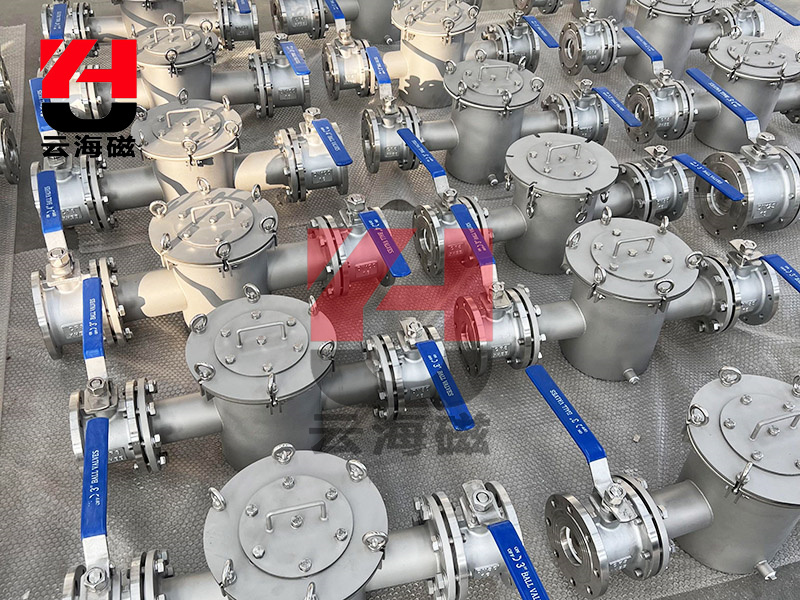

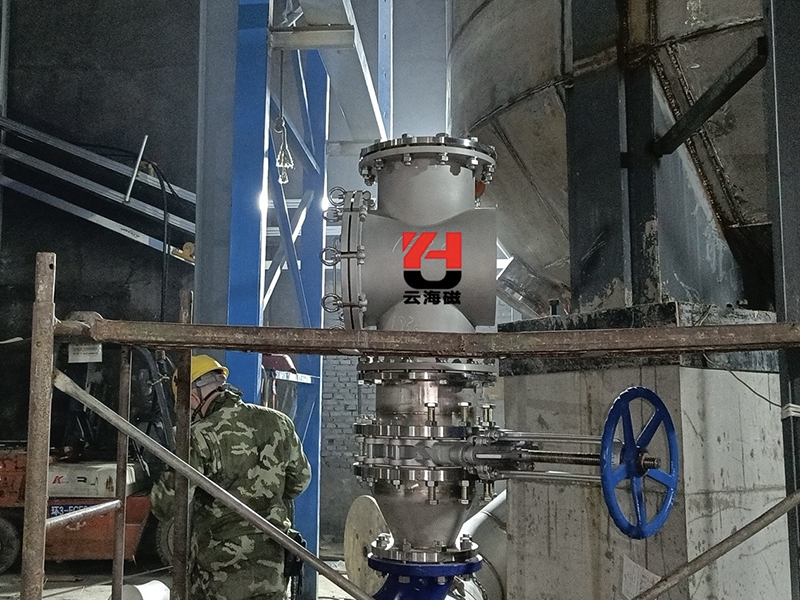

product image

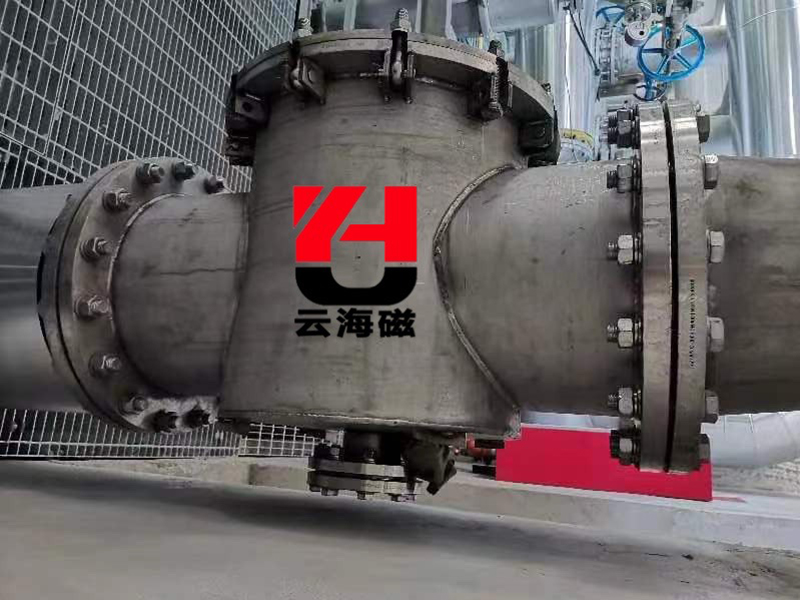

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE