CTG dry permanent magnet magnetic separator

Product Introduction

The CTG series dry permanent magnet magnetic separator can be designed and manufactured according to specific customer requirements with different specifications and magnetic induction strengths. It is suitable for various processing capacity requirements of mineral magnetic separation and can meet the iron selection needs of large, medium, and small mines. It is widely used in industries such as steel slag, river sand, ore, and metallurgy.

Scope of Application

The CTG series dry permanent magnet magnetic separator is mainly used for pre selection operations in each section after crushing, to remove mixed waste rock, restore geological grade, save energy consumption, improve processing capacity of the beneficiation plant, enrich crushed powder lean ore and extract iron powder from river sand. It is used in mining sites to recover magnetite from waste rock and improve the utilization rate of ore resources. It is also used to recover metallic iron from steel slag; Used for sorting useful metals in garbage disposal to improve the environment. The equipment has a simplified process flow, easy operation, saves a lot of labor, and has low production investment costs.

Technical Features

1. The magnetic system is made of neodymium iron boron material with strong magnetic force, large magnetic penetration depth, high remanence, and high coercivity, ensuring a high magnetic field strength on the surface of the drum. The magnetic system is wrapped in stainless steel skin to ensure that the magnetic block never falls off.

2. The cylinder body is made of high-quality stainless steel material, which can improve the wear resistance and service life of the drum, and is suitable for various harsh environments.

3. Non magnetic stainless steel material is used between the drum spindle and the magnetic system to ensure no magnetic leakage is transmitted to the spindle, thereby ensuring smooth operation of the bearing.

4. The drum can be used as both an active drum and a passive drum.

Technical Specifications

| model | roller diameter mm | roller length mm | Magnetic induction intensity of cylinder meter T | Selected granularity mm | processing power t/h | weight t |

| CTG-50/50 | 500 | 600 | 160-350 | ≤50 | 50-80 | 0.4 |

| CTG-50/65 | 500 | 750 | 160-350 | ≤50 | 60-110 | 0.5 |

| CTG-63/65 | 630 | 750 | 160-400 | ≤50 | 70-120 | 0.7 |

| CTG-50/80 | 500 | 950 | 160-400 | ≤50 | 70-150 | 0.8 |

| CTG-63/80 | 630 | 950 | 180-500 | ≤150 | 100-160 | 0.9 |

| CTG-80/80 | 800 | 950 | 180-500 | ≤150 | 120-200 | 1.4 |

| CTG-63/100 | 630 | 1150 | 180-500 | ≤150 | 130-180 | 1.5 |

| CTG-80/100 | 800 | 1150 | 180-500 | ≤150 | 150-260 | 1.9 |

| CTG-100/100 | 100 | 1150 | 180-500 | ≤250 | 180-300 | 2.6 |

| CTG-63/120 | 630 | 1400 | 180-500 | ≤150 | 150-240 | 0.2 |

| CTG-80/120 | 800 | 1400 | 180-500 | ≤150 | 180-350 | 2.5 |

| CTG-100/120 | 1000 | 1400 | 180-500 | ≤250 | 200-400 | 3.1 |

| CTG-120/120 | 1200 | 1400 | 180-500 | ≤250 | 220-450 | 3.5 |

| CTG-80/140 | 800 | 1600 | 180-500 | ≤250 | 240-400 | 3.7 |

| CTG-100/140 | 1000 | 1600 | 180-500 | ≤250 | 260-450 | 4 |

| CTG-120/140 | 1200 | 1600 | 180-500 | ≤300 | 280-500 | 4.6 |

| CTG-140/140 | 1400 | 1600 | 180-500 | ≤350 | 300-550 | 5.5 |

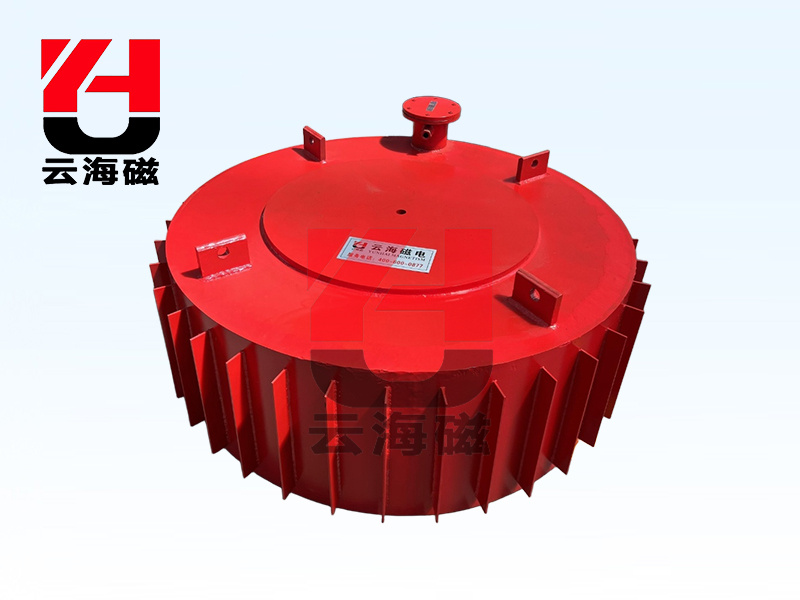

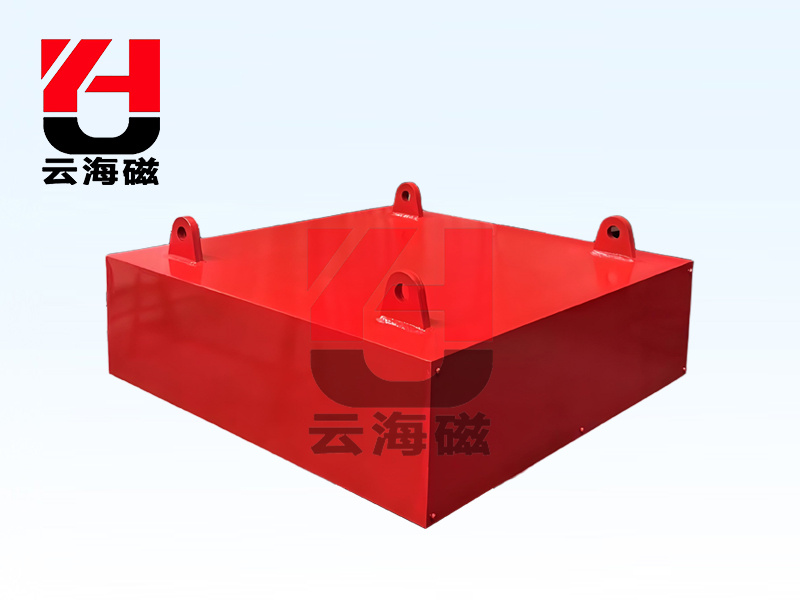

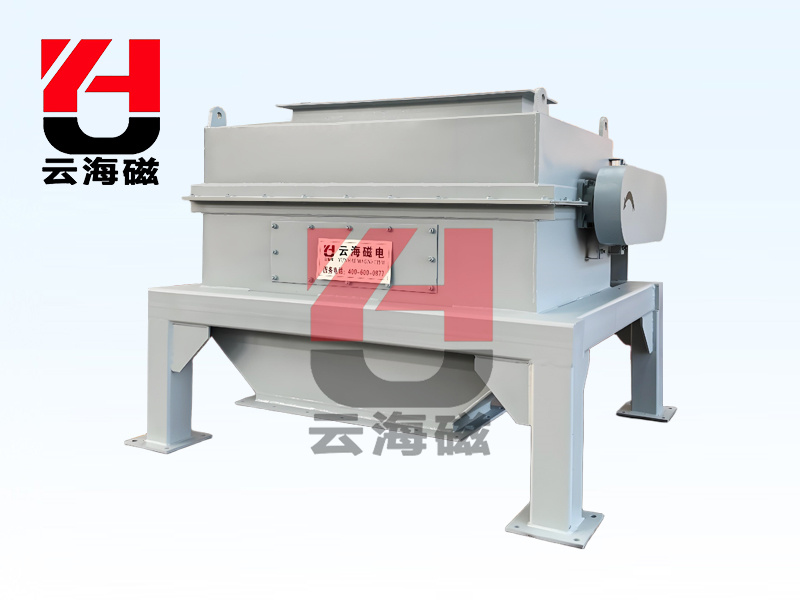

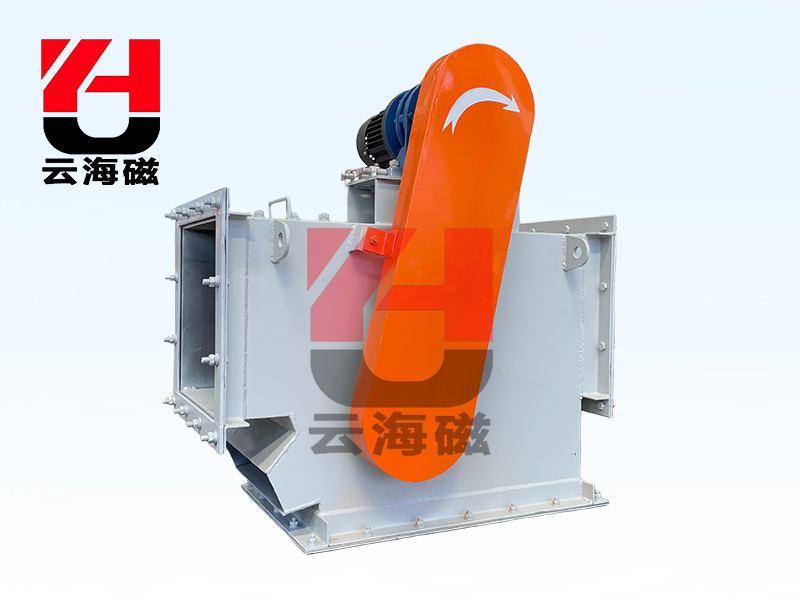

product image

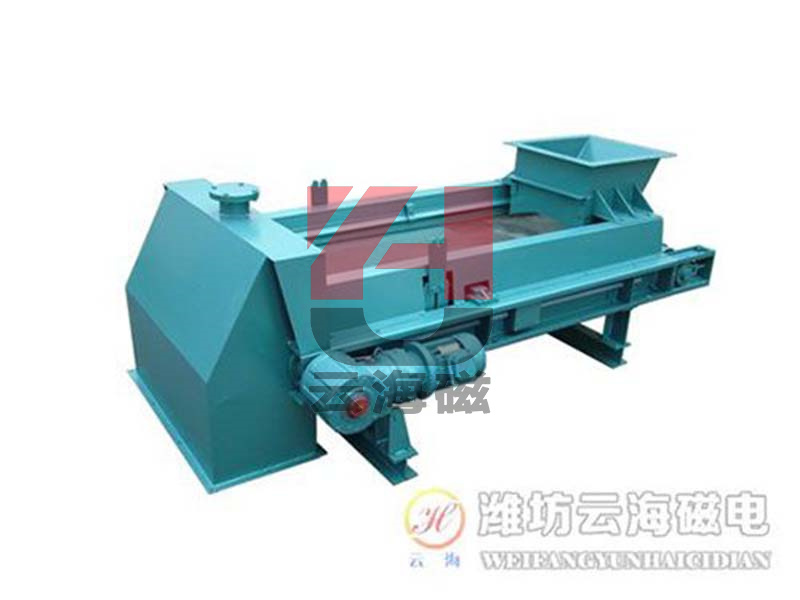

on-site installation

location:

location:

咨询电话:400-600-0877

咨询电话:400-600-0877

HOME

HOME

PRODUCT

PRODUCT

HOTLINE

HOTLINE