menu

Product

-

+

Company incorporation

-

+

reputable manufacturer

-

+

invention patent

-

+

product coverage

咨询电话:400-600-0877

咨询电话:400-600-0877

SPC series plate magnetic separator

SPC series plate magnetic separator

Manual response

Technical response

customized solution

Product advantages

Weifang Yunhai Machinery Equipment Co., Ltd. was founded in 2009. Its main products include industrial automation batching systems, electromagnetic permanent magnet separators, permanent magnet magnetic separators, electromagnetic vibration feeders, belt screw conveyors, electromagnetic drums, crushers, packaging machines, dust collectors, and other series of products. We have well-equipped laboratories and laboratories, hire industry experts to lead experiments and laboratory work, provide technical test data and research and development basis, and provide successful and effective iron removal solutions for various industries.

SPC series plate magnetic separator

Product Introduction

High strength plate magnetic separator: mainly used for iron removal of non-metallic minerals such as potassium feldspar, sodium feldspar, quartz sand, and kaolin, which can effectively improve the whiteness and quality of minerals. It has the characteristics of low energy consumption and no loss of finished minerals.

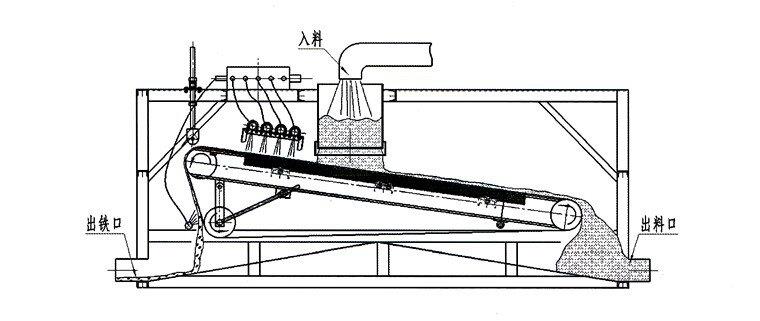

Flat plate magnetic separator (flat plate iron remover), comprising a frame, on which a magnetic separation mechanism, a tensioning mechanism, a water supply system, and a leveling device are installed. The leveling device is located above the conveyor belt between the low side of the magnetic separation slope and the water supply system. The leveling device includes upper and lower leveling layers, each leveling layer including a bottom with a dropping mesh hole and a blocking plate set around the bottom periphery. The dropping mesh holes are evenly distributed at the bottom of the leveling layer, and the blocking plate is connected at the beginning and end to form a feeding port. The aperture of the dropping mesh hole corresponds to the size of the mineral material. The leveling device includes a spray pipe located above the magnetic separation slope and connected to the flushing water inlet pipe. Directly below the spray pipe is a bottom with a uniform water passage. The sprinkler with holes has several downward spray holes on the spray pipe.

This utility model can evenly distribute the falling mineral materials on the magnetic separation mechanism, without accumulating into blocks. During the magnetic separation process, the mineral materials can be flipped according to the change of magnetic poles, greatly improving the accuracy of mineral material purification.

Technical Features

The flat magnetic separator effectively arranges over a thousand strong magnets to achieve a magnetic field strength of 15000GS on the entire surface of the flat plate, with a magnetic field gradient throughout the entire sorting area. It can effectively process various weak magnetic ores, especially for removing iron from limonite, hematite, ilmenite, manganese ore, garnet, gold steel sand, potassium feldspar, and silicon micro powder. It can also be used for high-purity iron removal operations on non-metallic materials, effectively reducing the iron content in potassium feldspar, fluorite, and quartz sand.

working principle

Using a belt sorting mechanism, the material is rolled multiple times in the sorting area from the feed to the discharge on the sorting surface, removing non-magnetic tailings. The magnetic minerals with magnetic properties are removed by the demagnetization device when the belt is transported to the demagnetization zone of the plate sorting machine to complete the beneficiation process and achieve good quality, which can achieve greater benefits.

Technical Specifications

| model | processing capacity T/n | power KW | Overall dimensions | weight | Remarks |

| 600×2000 | 8-10T | 1.5 | 4000×1000×1800 | 2.4T | |

| 800×2000 | 10-13T | 1.5 | 4000×1200×1800 | 2.6T | |

| 1000×2000 | 13-16T | 1.5 | 4000×1400×1800 | 2.8T | |

| 1200×2000 | 16-20T | 1.5 | 4000×1600×1800 | 3T | |

| 1500×2000 | 20-25T | 1.5 | 4000×1900×1800 | 3.5T | |

| 2000×2000 | 30-35T | 1.5 | 4000×2400×1800 | 4T |

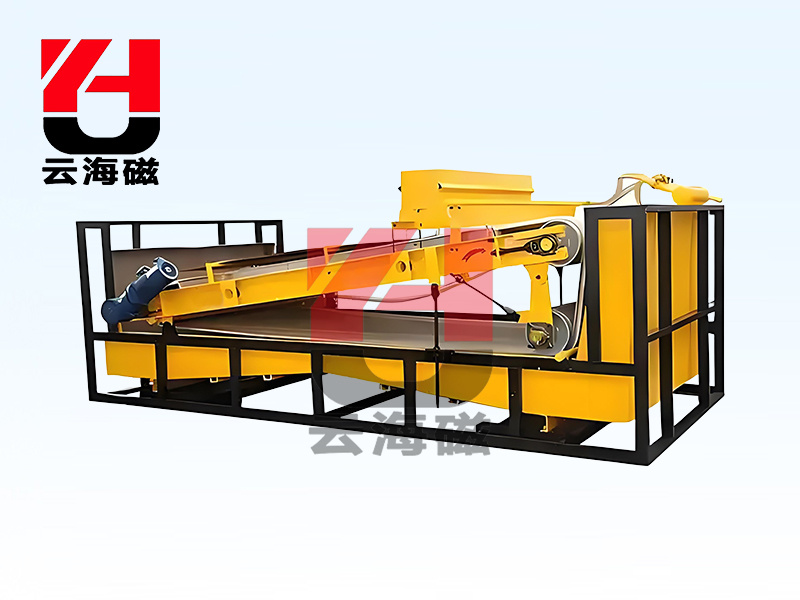

product image

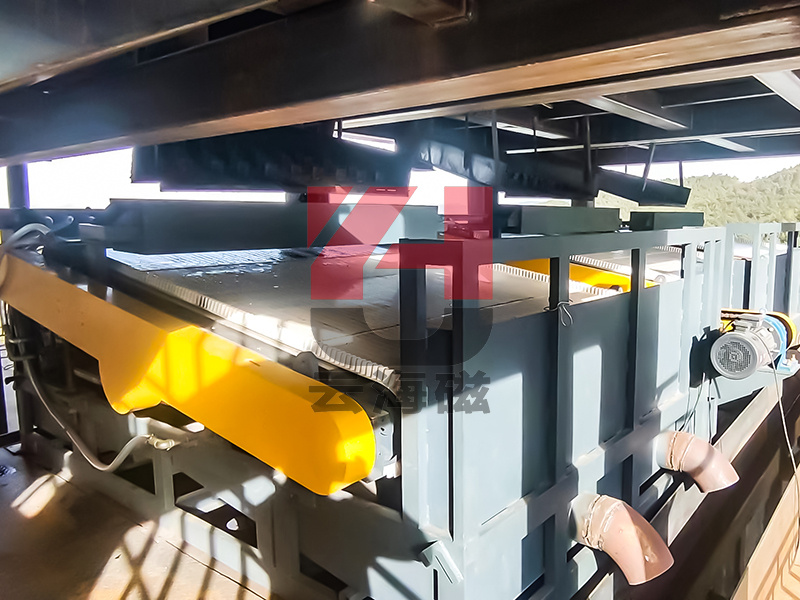

on-site installation

location:

location: